Environmental sustainability has become one of the main issues on a global level, and in particular when it comes to material handling the ecological awareness is getting stronger. More and more companies chose to be environmentally responsible and to invest in green solutions.

GREEN LINE is the Bolzoni green concept lift table range, with built-in ecofriendly technology. Here the lift table serves as a working station in a lawn mower assembly line. |

|

Bolzoni promotes environmental sustainable research and innovation and presents its ecofriendly

GREEN LINE Lift Table range with built-in technical innovations to improve efficiency and productivity.

For a lower impact on the environment, Bolzoni lift tables are available with biodegradable hydraulic oil on request, and are all provided with high-efficiency electric motors IE3. Lift tables are painted with water based nontoxic solvent free paint.

Built-in sustainable technology Lift tables are manufactured in Italy, in a dedicated area of 5.000 sqm in the Podenzano plant. The Bolzoni SpA facility is ISO 9001 certified since 1994 and obtained the Environment Certification ISO 14001:2015 in 2006. |

|

BOLZONI is a market leader in the development and manufacture of lift tables, and world-class specialist in forklift attachments and forks.

Since 1986 BOLZONI has designed and produced lifting tables for material handling specialists, with a full range of solutions, ranging from the ergonomic table to the dock loading bay.

In line with the European 2009/125/CE directive, Bolzoni is working to reduce energetic consumption, looking for ecofriendly solutions to improve manufacturing procedures and designing products able to reduce plant energy consumption.

Bolzoni designs a wide range of lift tables, with models and capacities suitable for use in production lines, for heavy duty applications, in assembly line as work station and, last but not least, in loading bay applications.

Thanks to their extreme safety and reliability features, these provide an effective solution to most lifting requirements.

GREEN LINE Line Lift Table 1E Each individual application needs a customized solution. Here a GREEN LINE lift table at the end of a production line, to collect and stack the plastic sheet rolls from the rewinder machine. |

|

Designed as a ''workstation'' this Bolzoni single scissor lift table provides improved ergonomic conditions to the operator. In facts, besides ensuring health and safety conditions, this lift table grants the best operator comfort, increasing productivity and efficiency.

In addition to the technical features of the whole range, this version includes:

- Aluminum safety bar stops the descent of the platform in case of contact with obstructions

- Single acting hydraulic cylinders equipped with hose safety valve, check valve and drainage.

- Low voltage "Hold-to-run" type control box

- Mechanical locks for safe servicing and maintenance operations

- Removable lifting eye(s) to make easier handling and installation.

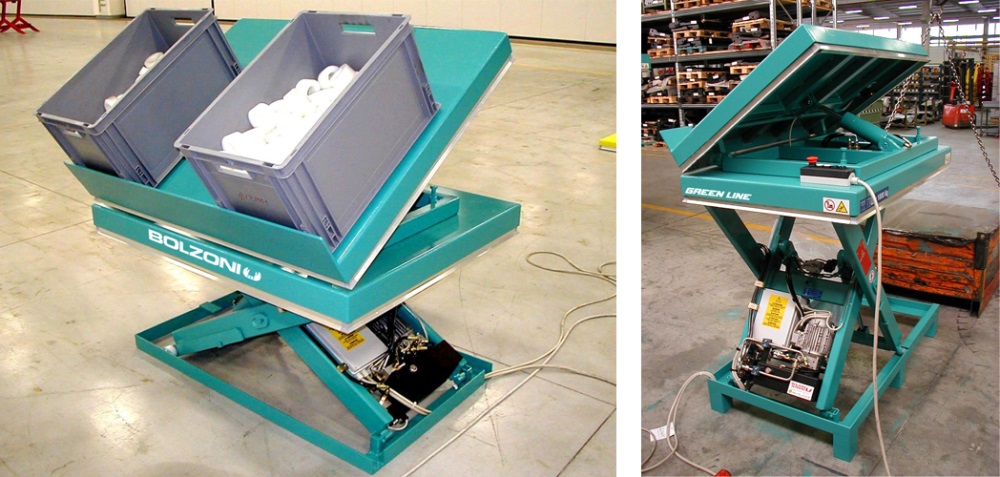

GREEN LINE Line Lift Table with Tilting Platform Specific to facilitate the picking of small parts, to reach load easily without operator bending or stretching: this is the GREEN LINE tilting platform lift table. |

|

Useful to raise and tilt containers, the

1E-T lift table allows operators to pick-up smaller parts tilting the platform to 35-degrees. Specially adopted in the automotive industry and assembly line in general, this product avoids adverse ergonomic conditions by giving the best possible relation between the operator and his work area.

GREEN LINE Low Profile Lift Tables No floor pit is required, as the closed height of this lift table is very low. This means, you can easily move it where you need it. |

Amongst the different models available, an interesting version is the

low profile lift table, an ideal solution for safe and economical material handling in assembling and packaging lines, logistic systems and stand-alone workstations.

Due to the low closed height, this scissor lift table does not require a floor pit, offering flexibility of application and location and keeping installation costs to a minimum.

The low profile lift table is available in three versions:

- C = closed top platform (access ramp is available on request)

- U = U-shaped platform, particularly useful when loading a pallet safely onto the table using a hand pallet truck or pedestrian truck without the need for an access ramp.

- E = E-shaped platform, offering superior pallet support, over the conventional "U-shape" platform.

Committed to qualityBolzoni is totally committed to continuous quality improvements, from product design to after-sale service. All lift tables comply with European standards and in particular with the Machinery Directive 2006/42/CE and Safety requirements for lift table EN 1570-1. Lift tables are supplied with CE Declaration of Conformity or Declaration of Incorporation depending on different configurations / uses.

For more information about

Bolzoni lift tables, please visit our website

https://en.bolzonigroup.com/lift_tables/ and contact us

by email, or contact the nearest

Bolzoni Auramo Meyer representative.

__________________________________

Bolzoni Auramo is a Bolzoni Group brand.

Bolzoni Auramo is a market leader in the production of forklift truck attachments, forks and lift tables. The company has manufacturing plants in Italy, Germany, Finland, America and China and through its network of direct branches and independent dealers covering all continents it is able to satisfy all market requirements. |

|