The logistics of the future starts today

In today’s industrial and logistics landscape, expectations are higher than ever. End users demand more from their investments: greater efficiency, enhanced safety, and uncompromising quality. To meet these demands, the material handling sector is rapidly embracing advanced technologies, sensors, and intelligent systems. Here is how companies can optimize internal logistics, starting from their forklift attachments.

At Bolzoni Group, we believe innovation should be practical, scalable, and future-ready. That’s why we’ve developed a full range of intelligent products that combine robust engineering with cutting-edge technology, designed to support modern businesses at every stage of their operations.

Modern warehouse operations demand solutions: Bolzoni's intelligent attachments are built to meet the challenge.

Modern warehouse operations demand solutions: Bolzoni's intelligent attachments are built to meet the challenge.

A range built on experience

With over 80 years of expertise in forklift attachment manufacturing, Bolzoni Group has always placed customer needs at the heart of its innovation. Our Intelligent Product range is the result of strategic investments in R&D and a deep understanding of real-world logistics challenges.

These solutions integrate sensors, laser guidance, and electronic control systems to:

- Improve visibility and precision during handling

- Minimize downtime and operational errors

- Actively assist driver decision-making

- Collect and analyze operational data for continuous improvement

Bolzoni's intelligent product range combines robust engineering with advanced technology to support every phase of logistics.

Bolzoni's intelligent product range combines robust engineering with advanced technology to support every phase of logistics.

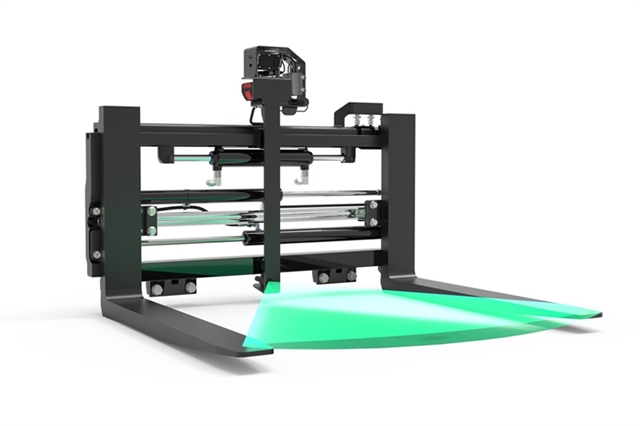

The Bolzoni Easy-FORK Vision System: full visibility, maximum safety

The Easy-FORK Vision System range is designed to significantly enhance safety and precision in warehouse operations, especially during high-level pallet handling.

Easy-FORK Vision System ensures maximum visibility, even in the most demanding operational contexts.

Easy-FORK Vision System ensures maximum visibility, even in the most demanding operational contexts.

The range includes three advanced solutions:

- Side fork camera: offers a 52° horizontal viewing angle, giving the driver a clear view of both forks while maintaining an ergonomic seating position, ideal for shelf-level operations.

- Tip fork camera: mounted directly at the fork tip, this robust camera with integrated triple LED lights ensures full forward visibility, even when the load is on the forks.

- Front camera and line laser: installed on the fork carriage, this system combines a 120° wide-angle camera with a Class 1 laser that projects a 90° reference line aligned with the fork tips. This solution is perfect for accurate pallet positioning even in low-light conditions.

All systems are available in wireless versions and are designed for forklifts up to 7 tons.

Bolzoni Intelligent clamping force control: easier handling, safer loads

Bolzoni Group’s intelligent clamping systems are designed to ensure safe, damage-free handling across a wide range of applications—from paper rolls to white goods and carton boxes.

“Thanks to their advanced features, these products actively support driver decisions in real time,” says Carlo Fallarini, Global Marketing Director at Bolzoni Group. “Plus, the ability to store and analyze operational data gives logistics managers powerful tools to optimize performance.”

These solutions combine sensors, microprocessors, and pressure control technologies to automatically adjust clamping force based on load type, weight, and configuration.

Bolzoni’s intelligent clamping systems support operators during handling operations, ensuring smooth performance and preventing goods damage.

- HTX – Automatic clamping pressure control system: this system automatically applies the lowest possible clamping force for each paper grade and handling situation, preventing roll deformation and ensuring high-value cargo protection

- Force-Matic generation 4: pressure control system that continuously adjusts clamping force based on load weight. Ideal for Auramo paper roll clamps, it eliminates over-clamping risks without requiring electronics

- Easy-FORCE-C pressure control system: a semi-automatic solution with cabin touchscreen interface, tailored for white goods and large logistics centers managing diverse load types

- Easy-MEASURE: a 4-point clamping force tester based on load cell technology. It measures and analyzes force distribution across the pad surface, helping logistics teams fine-tune their handling settings over time

- Easy-MOVE Intelligent carton clamp: uses laser beams and sensors to detect load dimensions and automatically set the correct clamping pressure via a proportional relief valve, perfect for mixed carton handling

AGV integration: attachments for autonomous efficiency

Bolzoni's AGV attachments integrate seamlessly with automated systems, enabling safe, autonomous material handling.

Bolzoni's AGV attachments integrate seamlessly with automated systems, enabling safe, autonomous material handling.

Automated Guided Vehicles (AGVs) are revolutionizing warehouse logistics by enabling efficient, autonomous transportation of materials and packages, without the need for human intervention. In this fast-evolving landscape, Bolzoni Group stands out as a trusted partner for AGV manufacturers and logistics operators, offering a complete range of intelligent attachments designed for seamless integration.

Thanks to years of cross-industry experience and close cooperation with leading AGV producers, Bolzoni develops both electric and hydraulic attachments equipped with advanced sensors, cameras, and control systems. These solutions are co-designed to meet customer-specific requirements and can be delivered as plug-and-play units, fully parameterized and ready for operation.

Bolzoni’s attachments-for- AGV are engineered to:

- Ensure precise, repetitive movements and safe load handling

- Eliminate hydraulic fluid risks with fully electric options

- Integrate directly with AGV control units for real-time responsiveness

- Adapt to diverse industries including paper, food & beverage, automotive, and logistics

For more information on Intelligent Solutions, get in touch with us, and ask for our references on Intelligent Handling Solutions, or to organize a demo unit at your facilities.

Visit the Solution for Industries section on our web site and contact us, or contact the nearest BOLZONI, AURAMO and MEYER representative.

Bolzoni, Auramo and Meyer are Bolzoni Group brands.

The Bolzoni Group is a market leader in the production of forklift truck attachments, forks and lift tables. The company has manufacturing plants in Italy, Germany, Finland, America and China and through its network of direct branches and independent dealers covering all continents it is able to satisfy all market requirements.