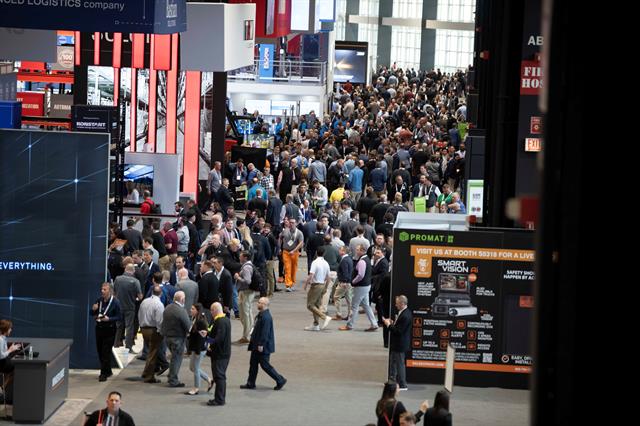

Record registrations at ProMat 2023 PHOTO: RAYMOND

Record registrations at ProMat 2023 PHOTO: RAYMONDProMat 2023, which wrapped up last week at McCormick Place in Chicago, Illinois, was held against a backdrop of intense interest in supply chain technology.

Organisers say this was the largest ProMat event to date for MHI, attracting more than 50,000 delegates - 12% more registered attendees than the last pre-pandemic show, ProMat 2019.

The event also saw a rebound in international attendance with attendees representing 178 countries.

“The success of ProMat 2023 is proof of … the supply chain industry’s continued relevance to the marketplace and central role in commerce,” says John Paxton, CEO, MHI. “No other event showcases all this industry has to offer to improve operational productivity and efficiency across manufacturing and supply chains. With so much tech and end-to-end solutions, ProMat offers this industry a one-stop-shop for solutions and the unparalleled education attendees need to survive, and even thrive, in a constantly changing marketplace.”

Daniel McKinnon, EVP of exhibitions at MHI, sees the energy on the show floor and the connections made during the four-day event as “a clear sign of the power of this industry”.

The Vetter team awaiting visitors at the start of the show

The Vetter team awaiting visitors at the start of the show

“Attendees representing the Fortune 500, the top 100 retailers and consumer goods firms brought large teams to ProMat to source the latest technologies and to learn leading trends impacting supply chains. They came to ProMat with plans in hand and budgets in place to improve their operations and build resilient supply chain operations for future success,” he adds.

The 2023 MHI Annual Industry Report, “The Responsible Supply Chain: Transparency, Sustainability, and the Case for Business”, released during the show, showed heightened awareness of the need to improve supply chain transparency and sustainability.

“Responsible supply chains must react in real time to changing conditions; this requires actionable data, automation and automated decision-making,” says Paxton. "Investments in automation and other digital solutions like IoT, advanced analytics and AI not only arm your operations with speed, accuracy and improved visibility, these solutions enable the real-time decision-making and transparency necessary for reporting and improving performance up and down the responsible supply chain.”

The report identified hiring and retaining qualified workers and the talent shortage as the top supply chain challenges, followed closely by supply chain disruptions, out-of-stock situations and customer demands.

ProMat organiser MHI used the show to announce the winners of the 2023 MHI Innovation Awards.

After receiving 156 submissions for the awards, judges named the following winners:

- Best new product: Agility Robotics

- Best IT innovation: OneRack

- Best innovation of an existing product: Hai Robotics

Enhanced data provider sSy.ai was presented with the 2023 MHI StartUp Award.

Innovations in traditional equipment

For US manufacturer Yale, ProMat was an opportunity to unveil an updated identity and brand positioning - Yale Lift Truck Technologies - reflecting the company’s focus on technology-enabled forklifts.

David Furman, president, marketing, strategy and business development, Yale, says it's time warehouse operations rethink what they expect from (forklifts), technology and suppliers. “That’s why we’ve invested in a more creative approach built around the customer, engineering lift trucks as smart technology foundations, and bringing innovations to market faster.”

According to Furman, the major topics of discussion at the Yale booth were labour, safety and productivity.

“Warehouses are definitely worried about the labour market and global labour trends, given that, according to the Bureau of Labor Statistics, warehouse turnover has hovered over 40% for five straight years.

“Visitors to the show, and our customers broadly, also voice awareness of the potential costs of accidents and other safety mishaps, and for good reason. According to the national safety council, work-related illnesses and injuries cost businesses USD171 billion annually and more than 7,300 forklift injuries occur each year. These issues drove conversations about lift truck solutions that can help operations get the most out of their workforce and help mitigate safety risks,” he tells Forkliftaction News.

Trade show visitors also got their first look at the Bobcat-branded materials handling equipment following the move away from Doosan branding to a new unified brand strategy.

Among the models shown in the new livery were D25S-9 and D70S-9 diesel forklifts, a BOP15S-9 electric order picker, a BR20SP-7P electric pantograph reach truck, and the new B30X-7 Hydrogen Fuel Cell Concept Forklift, initially announced as a research and development project in 2022 by Doosan Bobcat.

“As a company, we are evolving in bold ways to meet our customers’ toughest challenges by offering innovative solutions for a more sustainable future,” says Scott Park, Doosan Bobcat CEO and vice chairman. “Alternative-energy products — such as hydrogen or electric — give customers options, while also leading the way toward a more sustainable future and greener tomorrow.”

The Raymond stand attracted strong interest

The Raymond stand attracted strong interest

Toyota subsidiary Raymond had a range of machines on show, including the 8810 side-entry pallet truck, the 8530 rider stacker, 8630 tow tractor and the 4800 and 4810 sit-down electric counterbalance trucks.

Raymond Corporation president and CEO Michael Field highlights the Raymond High Capacity Orderpicker, “a first-of-a-kind lift truck that delivers market-leading capacity at all heights in various applications and helps optimise warehouse square footage by allowing for more usable space for product and improved SKU count and space allocation”.

According to Field, visitors were looking for information about new materials handling equipment, energy solutions, connected technologies and automation products that are designed to address their challenges and enable them to achieve maximum productivity, efficiency and visibility.

“Across the industry, operations are facing challenges and are working hard to try and solve them,” he says.

China’s Heli exhibited a number of forklifts “developed and designed in strict accordance with the North American market standards and customer needs”. More than 40 North American dealers were on hand to witness the launch of a new G3 series 3 T LPG forklift and a 2.5 T double-drive lithium electric forklift.

UK-based Narrow Aisle Ltd used ProMat to announce a distribution deal with Houston-based Equipment Depot, which will distribute Narrow Aisle’s range of Artix VNA warehouse trucks throughout the USA.

Equipment Depot sees huge potential to grow Artix articulated truck sales across America as the market for very narrow aisle (VNA) forklifts develops rapidly.

Narrow Aisle executive director John Maguire says: “The articulated forklift truck concept is well established in the USA and, with demand for more space-efficient warehouse solutions increasing, the United States has overtaken Europe as the biggest market for VNA truck sales during the last two to three years.”

HangCha, meanwhile, had 20 models on show and also used ProMat to release its new drop-in battery company, Universal Lithium Battery Solutions (ULBS). This new solution will allow end-users to convert their lead-acid electric materials handling equipment from any manufacturer to a lithium iron phosphate (LiFePO4)-powered unit, allowing older fleets to benefit from the latest battery technology.

Automation abounds

Big Joe, which earlier flagged a focus on automation, unveiled its Pallet Mover, a new user-directed autonomous mobile robot (AMR) developed in partnership with Thoro.ai.

Big Joe booth personnel

Big Joe booth personnel

The launch resonated with the strong visitor interest in automation, according to Big Joe chief marketing officer Bill Pedriana. “The Big Joe dealers were more excited about the Pallet Mover than we expected. The simplicity of the AMR makes it very attractive to them. A number of our dealers feel it will be a bridge to automation for them,” he says.

“The Pallet Mover is super simple to deploy and start seeing a return-on-investment on day one. The magic to that is our user-directed approach to automation, which, by nature, is focused on empowering workers and eliminating the need for complicated systems integration.”

France’s EasyMile demonstrated its TractEasy driverless tow-tractor at ProMat as it expands its footprint in the United States.

TractEasy is already deployed at a number of sites around the world to tow heavy items on cross indoor-outdoor routes. It uses a range of sensors and cameras with real-time processing to manoeuvre independently and efficiently.

China’s ForwardX Robotics used the show to introduce its latest autonomous forklift, the Apex C1500-L.

The forklift can identify the angle at which a pallet is placed and adjust autonomously in real-time to complete its task even when a pallet is misplaced. The new forklift was designed with multiple workflows in mind, including receiving, put away, restocking, cross-zone handling, conveyor docking, and outbound workflows.

Canada’s Otto Motors displayed its newest AMR, the OTTO 600, which it claims is the toughest and most nimble AMR in its class. The AMR can move pallets, carts and other payloads up to 600 Kg.

The company also unveiled its latest software release, 2.28, with a new facility configuration interface for quicker workflow set-up.

Otto attracted plenty of visitor attention, according to Jay Judkowitz, VP of product, who says there were fewer conversations about the difference between an AMR and an AGV and more conversations about the urgency of automation. “Everyone is trying to increase production, make retooling possible, increase business continuity, improve employee safety, and/or bring production home to make the supply chain more resilient. And, they're trying to do this with less access to labour than ever before,” he explains.

“Customers across many industries are increasingly realising that they can have the safety, predictability and labour savings of AGVs without sacrificing the flexibility and adaptability in tight spaces of human drivers, as delivered through AMRs. This is important because most manufacturing is not truly ‘lights out’. Customers need autonomous materials handling that can share the space with people and other automation without risking accidents or traffic jams.”

Tompkins Robotics introduced a new Induction Lift and a new multi-function robotic sortation system at ProMat. The Induction Lift system eliminates the need for pre-sorting of items and allows for a larger, more efficient batch pick process upstream of the order sortation process. The multi-function robotic sorter system, meanwhile, sorts items going to unique orders on one level of a tSort system and sorts the outbound parcels on another level.

“The ability to sort items and outbound customer parcels in the same system is a breakthrough in technology and will be a game-changer in the e-commerce fulfillment industry,” says president and CEO Mike Futch. "Shippers can achieve huge benefits through reductions in cost, space and complexity with the multi-function sorter."

Industrial giant Siemens used the show to announce the formation of the new intralogistics vertical that brings best-in-class materials handling thought leadership, hardware automation, software and service solutions to customers in the United States. Siemens is leveraging its broad technology to address the market needs for digital transformation, cybersecurity, safety and sustainability.

Joel Thomas, head of the new division, says: “The goal for all companies should be smart manufacturing and automated material flow, which is adaptable to changing market and technology conditions. This is especially challenging in older brownfield operations, where the legacy equipment might not handle the needs of the company, tomorrow or even today.”

He adds that the intralogistics business will help companies achieve a more productive eco-system and, with various Siemens solutions and services, a homogenous environment in the future-proofing of their operations.

Vecna Robotics had its full range of autonomous mobile robots and co-bots on display. The stand also had information on Robots as a Service (RaaS), navigation, and autonomy using the Vecna system.

Matthew Cherewka, director of product marketing, says visitors were keen to talk about ROI and productivity improvements. There was also strong interest in customisation. “A ton of prospects have highly unique or corner case automation needs,” he says.

“At Vecna Robotics, we believe that customers should automate the most common tasks first, instead of trying to apply automation to highly custom workflows that are untested.”

Vecna is extremely optimistic, he adds, with data suggesting that more than 80% of its target market (mid to large warehouses and manufacturing in target verticals) will adopt some amount of automation this year.

Attachments and accessories

The Vetter team awaiting visitors at the start of the show

The Vetter team awaiting visitors at the start of the show

German fork manufacture Vetter used ProMat to showcase its newest SmartFork developments with additional features to increase safety and efficiency for the forklift operator.

Oliver Lotz, Vetter US sales manager, says safety was the hot topic at the company’s booth. “More than 50% of the visitors have daily issues with damage caused by bad visibility for the truck operator. Close behind were concerns about training unskilled drivers to get familiar with their tasks.

“Correspondingly, visitors were highly impressed by the solutions Vetter has on offer,” he says, adding that significant orders were notched up during the show, including one for 10 sets of SmartForks from a single customer.

Lotz notes that order books in the United States are full, but predicts fewer new orders this year in what will be a return to normal trading. However, supply chain challenges persist and risks like international tensions still threaten all sectors.

Cascade unveiled the next-generation Electric Mast from mast manufacturer and Cascade subsidiary Lift-Tek, combined with Cascade's Electric Sideshifting Fork Positioner. The new mast offers even faster lift speeds for greater productivity gains in warehouse applications.

Cascade also exhibited its latest mobile weighing solution, the Cascade ActivWeigh weighing carriage. Available as an integral or hang-on unit, this patented product is a carriage-based scale which integrates Weigh-In-Motion capabilities with sideshifting and fork positioning functionality.

Reading, Pennsylvania-based EnerSys unveiled its NexSys AIR wireless charger at ProMat, promising a ‘virtually maintenance-free, chemistry-independent charging solution for lead-acid, Thin Plate Pure Lead (TPPL) and lithium ion batteries.

“The new NexSys AIR wireless charger delivers the convenience of a reliable, hands-off charging solution,” says Harold Vanasse, senior director of marketing, motive power - global at EnerSys. “Along with charging a range of equipment and battery technologies, our NexSys AIR wireless charger can drive safety and productivity by eliminating the need for extra personnel to physically plug-in automated equipment, something especially important with today’s labour market.”

Cascade showed off its ActivWeigh

Cascade showed off its ActivWeigh

Burlington, Vermont wireless charging provider Resonant Link showed off what it claims is the world’s “fastest, safest and most reliable wireless charger for … materials handling equipment”.

Resonant Link’s wireless, automatic fast charger works with both autonomous and manual vehicles, with a tolerance of 6 in. (15 cm) misalignment and an air gap of 10 in. (25 cm).

“Anything that improves the operator's day-to-day experience is worth investing in,” says Grayson Zulauf, Resonant Link’s CEO. “To fully realise the benefits of wireless charging, we’ve built charging to be seamlessly integrated into fleet workflow, to be able to stop and start automatically and nearly instantaneously, and to work with every vehicle without maintenance.”

Fuel cell innovator Plug Power’s ProMat booth featured a 3D model of Plug’s fuel cell, a hydrogen dispenser with simulated refueling, and an interactive application highlighting its green hydrogen turnkey solutions.

The company also announced a new hydrogen fuel cell solution for forklift fleets of 100 or fewer, which represent more than 25% of all forklifts sold in the US.

Vice president of sales Tim Terrill tells Forkliftaction News many ProMat attendees are looking to move from lead-acid or propane to hydrogen fuel cells and are challenged to increase electrical load on their facility. “The additional power requirements cannot be supported by the area or grid,” he says, “(but) hydrogen would reduce their electrical need and provide a green solution. Sustainability and green solution conversations are increasingly more important to all businesses.”

The energy exhibits were not limited to productivity enhancement, with Sunlight Group announcing a lithium battery recycling project developed in collaboration with a consortium of partners.

EnerSys debuted a new wireless charger

EnerSys debuted a new wireless charger

The ReLiFe Project addresses the EU directive regarding batteries and relevant targets for material recovery and will run for three years. Its initial aim is to establish a pilot plant with a recycling capacity of 500 T of lithium batteries per year at Sunlight Group’s production facilities in Xanthi, north eastern Greece.

Safety solutions provider Advanced Microwave Engineering (AME) debuted its Amesphere proprietary platform at ProMAT.

“We have created Amesphere as a subscription-based solution so that customers can select the exact services they need and get the best value from their investment,” explains Filippo Bonifacio, CEO and vice president of AME.

He says visitors discussed the necessity to elevate safety in their plant and warehouse, both for pedestrians and vehicles, and also the need to reduce near-misses and hazardous accidents. “The discussion was also about the latest trends and technologies in the field of plant and warehouse safety and how our solutions can help them stay ahead of the curve. The discussions centred around the need for effective safety solutions that can help prevent accidents, minimise damage, and improve overall efficiency in their operations.”

According to Bonifacio, “While the US market is highly advanced in terms of cargo handling, we think that there is still room for improvement when it comes to safety. We believe the US lags behind Europe in this area and that there is significant potential for AME's solutions to make a difference in the market.”

A human touch

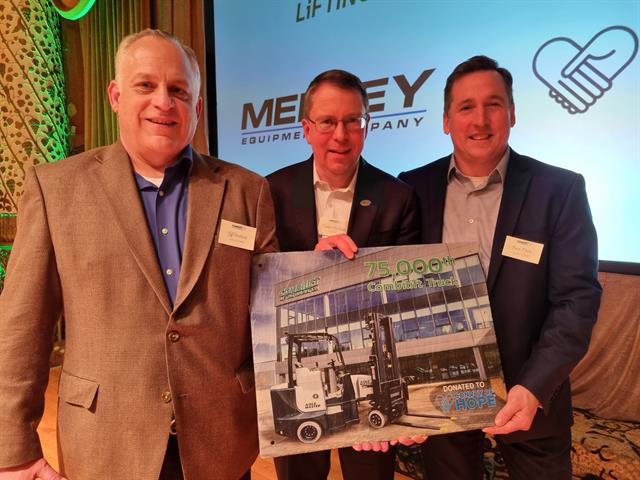

Jeff Smethers (Convoy of Hope), Martin McVicar (Combilift) and Erick Meier (Convoy of Hope)

Jeff Smethers (Convoy of Hope), Martin McVicar (Combilift) and Erick Meier (Convoy of Hope)

Ireland’s Combilift took advantage of the attendance of its dealers and customers at ProMat to stage a celebration of its 25th anniversary.

As part of the festivities, CEO and co-founder Martin McVicar announced the donation of the company’s 75,000th truck, an Aisle Master articulated forklift, to Convoy of Hope, a non-profit humanitarian and disaster relief organisation.

The truck will be sent to the organisation’s Springfield, Missouri distribution centre from which truckloads of relief supplies and food are sent on their way across the USA and further afield around the globe. Combilift supplied its first Aisle Master to this site four years ago, and a further three units were delivered last year.

- The next MHI-sponsored trade event will be MODEX 2024 held on 11 – 14 March in Atlanta’s Georgia World Congress Center. The next ProMat will be held at Chicago’s McCormick Place in 2025.