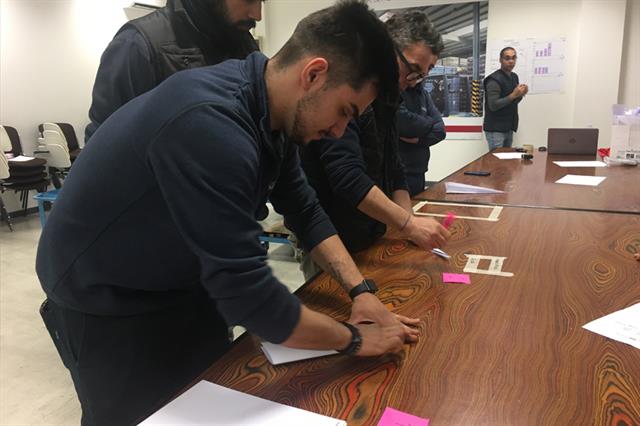

Production line at Bolzoni-Auramo Forklift Truck Attachment Co., Ltd. in Wuxi, P.R.C. |

Always move forward with ideas and people: this is the path we follow in Bolzoni Auramo.

In a continuously evolving world, to be prepared to changes and to surf challenges is every company goal.

Bolzoni Auramo, as several excellent organizations world wide, found the way to quality improvement in the adoption of the Lean Manufacturing System.

With

seven production sites situated in Europe, America and Asia, Bolzoni Auramo is strongly focused on organization and production improvements. We asked Roberto Brusamonti, Bolzoni SpA OEM's Production Manager and responsible of the Lean Manufacturing System implementation inside the Bolzoni Group, to share his experience.

Roberto Brusamonti is not too tired to run around the Bolzoni Group manufacturing plants to share the lean vision and methods with colleagues all over the world. He has been working in Bolzoni for 26 years and he is responsible for the Lean Manufacturing implementation process inside Bolzoni since 2010, when Roberto Scotti, CEO of the Bolzoni Group first embraced the Lean Manufacturing philosophy to make the company more competitive. Through consultants executive coaching and mentoring, as a waterfall first in Italy, second in Germany, in P.R.C., in the US and in all other group production plants, Roberto is carrying out dedicated lean manufacturing workshops.

Mr. Brusamonti, tell us about this project. How does this system help Bolzoni?"Continuous improvement through waste reduction and production processes optimization are not a question of chance. This system helps us to be a growing company, even in hard times, and through market crisis.

Bolzoni SpA production premises: workers take part to the ''Lean Simulation'' workshop. |

|  Roberto Brusamonti, met our Sulligent Colleagues in Alabama, USA. |

|

"Lean philosophy is at the production and logistics basis, giving guidelines for the interaction with customers and suppliers. In facts, the lean methodology brings quality and efficiency improvements through the whole management chain.

"We only focus on what is needed, systematically reducing wastes, and this increases the customer perceived value in term of quality, delivery and cost performance. We don't have a magic wand, but the awareness that we need to improve day by day. To become preferred supplier doesn't happen by chance."

Does Bolzoni have a lean recipe?"The majority of people involved in manufacturing processes know about Lean methodologies: 5S, Value Stream Mapping, SMED, KANBAN, one-piece-flow, zero defect principle.

We start from the actual situation analysis, the processes mapping, we choose the field we want to improve and put down a plan of activities and the implementation to each of them." Isn't it simple as ABC? "In Bolzoni we focus on what the true value to customer is: the value is an action, a process the customer accepts to pay for: all the rest is waste."

What does 'lean oriented' mean? How do you involve workers? How do you ensure the values are aligned internally and externally?"One of the Lean System Principles is 'create and transfer of knowledge', and this is why, to optimize efficiency, we are implementing it in all Bolzoni Group manufacturing plants.

Roberto Brusamonti met our Colleagues in Wuxi, P.R.C. |

|  "In the fork painting dept., we spared enough varnish to paint the size of six football fields" |

|

"We ask for the engagement of all the people inside the company. We believe this cultural change creates advantages for everybody. In Bolzoni we feel it is strategic to transfer knowledge and involve workers, through periodic meetings, showing obtained results and sharing new projects. To keep everybody involved and lean oriented we practice workshops inside our production plants world wide. Through team work sustainment we get to the final result. Improvement triggers improvement."

Mr. Brusamonti, can you tell us about some success stories you achieved in the Bolzoni Group manufacturing plants? "Since 2011, thanks to external consultations, the integral sideshifters assembly line process has been optimized, continuously improving along the last 8 years, with a result of 40% productivity improvement.

Roberto Brusamonti, Bolzoni SpA OEM's Production Manager, has been working for Bolzoni since 1993. |

"Another remarkable result I can mention has been obtained in the fork painting area: efficiency has been improved thanks to the strong reduction of varnish consumption. The overspray has been put under inspection and some actions have been undertaken: redefining the system parameters, though keeping customer expected quality. The result has been great: the varnish consumption has been reduced by 22% during 2018. We spared enough varnish to paint the size of six football fields. Figures matter: 381 kg less of solvent emissions into the atmosphere and 3.060 kg of special waste not produced.

"In Shanghai, during a workshop carried out in 2019, the integral attachments assembly line waste has been analyzed and the motion time has been reduced by 60%. Achieved result? Each worker walks 2 km less a day."

Bolzoni Auramo will be exhibiting at IMHX 2019 from 24-27 September at NEC Birmingham, UK. Visit us at stand 20C50!

For more information on Bolzoni Auramo products, please visit our website

www.bolzonigroup.com and contact us

by email, or contact

your nearest Bolzoni Auramo representative.

____

Bolzoni Auramo is a Bolzoni Group brand

Bolzoni Auramo is a market leader in the production of forklift truck attachments, forks and lift tables. The company has manufacturing plants in Italy, Germany, Finland, America and China and through its network of direct branches and independent dealers covering all continents it is able to satisfy all market requirements.

|

Get in touch with Bolzoni SpA (Group HQ)

-

Thank You

- Someone will contact you soon.

Via I Maggio, 103

I-29027 Casoni di Podenzano,

PC, Italy

To learn more about impactful advertisements:

download our media kit

The article on this page is supplied by and shown on behalf of an advertiser and does not in any way represent the views of Forkliftaction. The originators take full responsibility for their content. We advise you to contact the advertiser directly for any matters concerning this article.

Make an impact on your target market!

Business people who like to make informed decisions about the materials handling fleet and operations within their organisation, subscribe to Forkliftaction.com, the biggest online news service and business forum about materials handling.

Publish your press releases, use cases, new product releases and business announcements in Forkliftaction News, and make an impact on a niche and focused opt-in audience.

Inside The News

In this week’s Forkliftaction News , hydrogen power is a theme as we report on the US marking its 10th annual National Hydrogen and Fuel Cell Day, an initiative to promote the benefits of the clean energy source...

Continue reading

Inside The News

In this week’s Forkliftaction News , hydrogen power is a theme as we report on the US marking its 10th annual National Hydrogen and Fuel Cell Day, an initiative to promote the benefits of the clean energy source...

Continue reading

Inside The News

In this week’s Forkliftaction News , hydrogen power is a theme as we report on the US marking its 10th annual National Hydrogen and Fuel Cell Day, an initiative to promote the benefits of the clean energy source...

Continue reading

Your browser is out of date!

This website is best viewed in Internet Explorer 10 or above.

Please update your browser to view this website correctly.

Update my browser now

×

Welcome to Forkliftaction.com!

Thank you for visiting and being a part of

our story.

We hope you enjoy the celebrations as they unfold.