The advantages of a compressed air forklift over an electric forklift are numerous.

PHOTO: ENGINE AIR |

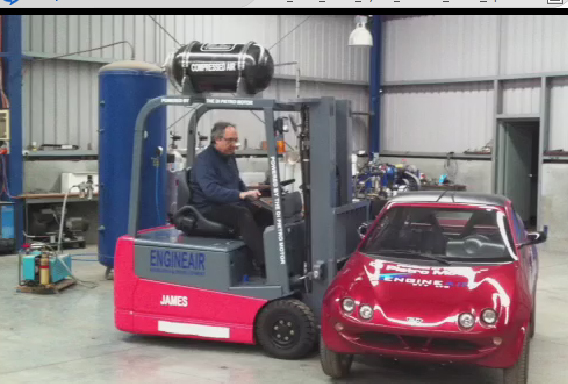

The forklift that runs on compressed air, flagged earlier in

Forkliftaction.com News #411 has arrived. The project to convert a forklift to operate using compressed air instead of batteries was undertaken by Australian inventor Angelo Di Pietro and his associate Dr James Ma last year and recently completed.

Ma tells

Forkliftaction.com News that some minor adjustments still need to be made, but the forklift is able to operate on a continuous basis for around two hours. It uses two air tanks with a total capacity of 100 l at a pressure of 350 bar.

The advantages of a compressed air forklift over an electric forklift are numerous. Batteries are expensive and take hours to be charged and have a limited life of no more than 2,000 charge cycles. Compressed air can be charged up in a matter of minutes from a filling station. Air tanks virtually have an unlimited life and can be refilled hundreds of thousands of times.

A compressed air forklift is ideal for warehouse applications where zero pollution is required. The compressed air drives the motor without any combustion or harmful exhaust gases.

Di Pietro won the ABC's New Inventors show in 2004 when he demonstrated air motor technology based on his unique rotary piston concept.