EP's wide selection of electric warehouse equipment has been extended with the AC series. New compact design and the ergonomic "creep" operation ensure the EPT-20-20WA provides an ideal solution for both ease of operation easier and space saving.

Latest AC technology:The latest Zapi AC drive system is employed in new generation, delivering high performance with the efficiency of the AC controller and drive motor. These ensure the truck responds to the slightest command from the driver, provide excellent acceleration for high throughput, more power, higher drive speed and, higher productivity and maintain travel speed in every situation - especially on slopes.

Integrated energy reclamation during braking, while automatic braking prevents unintentional roll-back on ramps. The models also boast reduced motor heat, faster heat dissipation and lower energy consumption. A fully enclosed construction means higher resistance against dust and moisture. No-maintenance parts such as carbon brushes mean higher reliability and less maintenance.

Click to Enlarge |

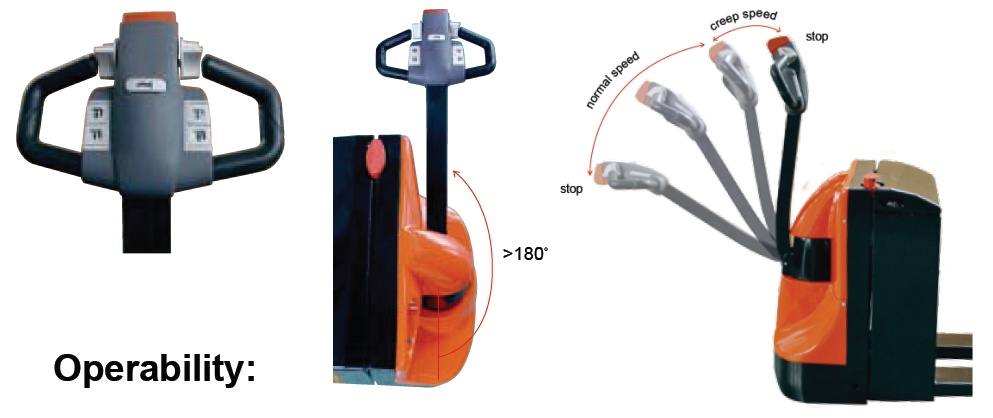

Operability: The spring caster optimises the stability of the truck in any situation. EP's new control handle can provide safe and smooth operation for driver. The lifting & lowering buttons are easily accessed and operated by fingertip with either hand, without removing the operator's hands from the tiller head. Steering handle rotates more than 180 degrees with minimal effort and positive control for excellent manoeuvrability. Gas-assist springs provide effortless positioning and controlled return of the handle to a vertical position. A long-arm handle on the EPT-20-20WA makes steering and manoeuvring easy. With minimal force required to pull down the one piece tiller, the driver can walk either behind the truck or beside it.

Click to Enlarge |

Durability: A heavy-duty MONARCH hydraulic motor is integral with the pump and reservoir to assure positive alignment and maximum strength. External cut-off switch plus mechanical stop saves energy and prevents motor overload when forks have reached full height. The drive unit gearbox is designed for ease of maintenance. All gears are immersed in an oil bath for long life and quiet operation. The tapered fork design provides industry-leading pallet entry and exit. And its one-piece overall design gives the truck added stability and strength when loading. The durable special designed ball bearing steering system provide an easier, reliable steering operation, both with and without loads. High position lift-arm design makes the system pressure very low, and the saved pressure brings long operating time for battery.

Click to Enlarge |

Serviceability: Easy access through an easy-open top cover gives technicians total access to key components. The casters can be released quickly and easily through a borehole in the chassis apron. Low-maintenance electric park brake. Fused traction controller. All operation switches in tiller head can be replaced as complete kits. Bushes on all pivot points, and optional grease fittings on all lift linkage and steering points. Diagnostic handset. Hinged battery cover can be easily opened with wide angle. Apply connectors through out complete harness set, no welding connecting. Hydraulic reservoir cap makes top-up easy. The creep speed control allows the driver to operate the truck in tight areas with the handle nearly vertical for tight turns, saving nearly 30% of the required manoeuvring space.

Safety: Side-in design of key & power meter install saves space and guarantees component safety. The truck body goes all the way down to the floor, wheels turn within the confines of the chassis, which can reduce the risk of trapped feet, etc.. Battery tray is locked by a spring tab which can prevent battery movement when the truck is travelling and decrease the risk of battery damage or acid leakage. The emergency stop plug are all mounted at the right side of the truck body, the driver can take action immediately in case the emergency take place. Big contact size safety belly button on tiller head in event of contact with the operator.

Click to Enlarge |

Click to Enlarge |

|

Click here to view the EP Shopfront