Companies are turning to data to manage their fleets

Companies are turning to data to manage their fleetsWhile it is true that we can’t yet talk about COVID-19 in the past tense, we appear to be over the worst in terms of lockdowns and economic disruption. As such, as with all industries, now is a good time to consider the effects the years of disruption have had on materials handling and, more specifically, on fleet management technology.

Fleet management systems enable the management, tracking, maintenance and accounting of vehicles, equipment and fleets and are gaining traction as materials handling operations get bigger, more costly and more complex.

Impco's Optafleet Fleet Management System is designed to provide information about relevant vehicles

Impco's Optafleet Fleet Management System is designed to provide information about relevant vehicles

According to industry insiders, the effects of the pandemic have been mixed. Impco Technologies, for example, actually experienced growth in the first year of the pandemic (2020), although at a lower level than would have been expected before COVID-19 hit. “2021 was yet another good year, but there again, the semiconductor shortage started to have an impact on sales,” says managing director Serge Vartanian. “This year, we started off very strongly again, but the shortages continue to play an important role.”

Beyond these supply chain concerns, as Steve Coley, managing director of Transmon Engineering, points out, the pandemic has also introduced an element of caution and slowed capital expenditure. “On top of that, access to customer sites has been limited during various periods. However, this has now eased and we are actively carrying out visits to our customers at their premises,” he says.

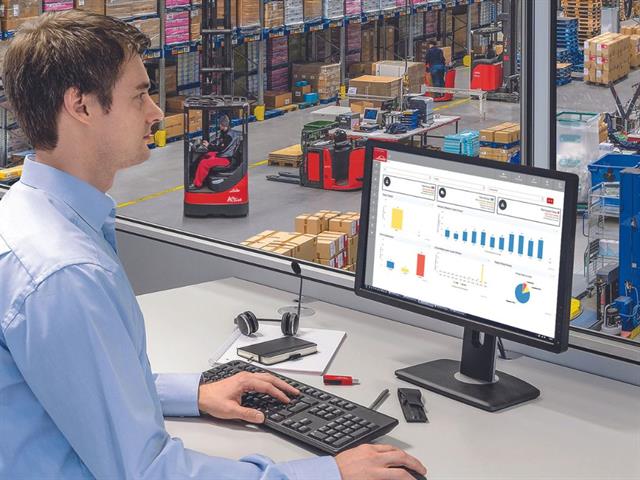

At the same time, the pandemic brought some unexpected benefits. As Stuart Hitchens, national fleet contracts manager at Linde Material Handling, explains, because a lot of in-store shopping became impossible during lockdowns, online retail expanded dramatically. As a result, businesses struggled to keep up with demand, and eventually turned to fleet management software as a way to improve efficiency.

Development and innovations

FMS is able to empower its customers to analyse their forklift and pedestrian interactions

FMS is able to empower its customers to analyse their forklift and pedestrian interactions

In this context, as we move further forward from the disruptions of the last couple of years, it makes sense to outline the latest technologies available in this space and explain the ways they can improve safety and efficiency.

According to Richard Gibbs, sales and marketing manager at FMS Technology CC, the integration of control systems and telematics management solutions within fleet management systems has resulted in improved safety.

“Clients now understand that a telematics management unit, no matter how specialised, will not reduce risk to an acceptable level. Management units should be used to monitor the control systems in place on the forklifts and machines to ensure safety,” he says.

“Products like speed restrictors and pedestrian detection systems should be used to control the movement of pedestrians and machines. The management units should monitor, not only driver and machine performance, but the functionality of the safety systems in place.”

By integrating Artificial Intelligence cameras with management databases, FMS is able to empower its customers to analyse their forklift and pedestrian interactions, highlight hot spots and danger areas, and implement appropriate safety measures.

Manufactured by Impco Technologies and used in combination with the company’s Optasafe Pedestrian Detection Solutions, the Optafleet Fleet Management System is designed to provide accurate information about what is happening around the immediate vicinity of relevant vehicles.

Where the system is deployed, drivers have access to a monitor and when pedestrians enter nominated zones, an alarm is activated. When this occurs, the truck is reduced to turtle speed and relevant data is transferred to the system.

To improve communication between vehicles and the back end, IoT-based communication using the 4G and 5G (LTE) networks is employed, along with 2G as a fall-back. This new IoT protocol ensures superior penetration into buildings and even basements.

The Transmon ACAS is an all-round solution to forklift safety in warehouse environments

The Transmon ACAS is an all-round solution to forklift safety in warehouse environments

The Transmon Active Collision Avoidance System (ACAS) is an all-round solution to forklift safety in warehouse environments, production areas, loading yards and outside depots. It uses sensors surrounding the vehicle which provide the driver with accurate information about the space behind and to the side of his/her current position. Having this level of visibility significantly increases site safety, provides driver reassurance, and sets the scene for improved performance.

A fleet management solution suitable for mixed industrial fleets and vehicles of all makes and models, GemOne’s Onyx fleet management solution includes several innovations, such as the addition of CAN data, a battery power tracker, and a battery monitoring solution.

The Controller Area Network (or CAN) bus allows the machine's devices to communicate with each other. This CAN data functionality equips businesses with real-time information on the status of their machines, helping them to improve machine safety and boost fleet productivity. For example, it allows management to measure the exact hours a machine is being used and in which locations. This data is available as a live overview on the GemOne Cloud at any time, from any device.

Linde's Fleetfocus includes a dual WI-FI GPRS (3G and 4G) system

Linde's Fleetfocus includes a dual WI-FI GPRS (3G and 4G) system

An Australian-made and -managed fleet management system launched by Linde Materials Handling in 2007, Fleetfocus includes a range of industry-leading features like a dual WI-FI GPRS (3G and 4G) system which works much like a mobile phone, where depending on the current location of the vehicle, the system can automatically switch between the two; and a display screen saver, which is specifically designed for night use to reduce operator glare.

On top of that, customers are able to temporarily hire units via Linde’s fleet management system, and are invoiced for the time used.

Broadening uptake

One overall trend associated with these products is their broadening appeal. Although they were initially used exclusively by larger materials handling operations with the financial means to push technological boundaries, fleet management systems are now employed by businesses of all sizes.

GemOne's Onyx fleet management solution includes several innovations

GemOne's Onyx fleet management solution includes several innovations

“Track and trace functionality allows smaller companies to know where each machine in their fleet is located, when it is being operated, and when it is due for maintenance. In this way, smaller companies can eliminate both underuse and overuse of their machines and optimise how they’re using each and every vehicle,” says Patrick Smets, CEO of GemOne.

“For smaller companies with smaller maintenance teams, the insights provided by fleet management solutions ensure businesses can enhance the servicing of machines, both in corrective maintenance as well as in preventative maintenance.”

According to Smets, improved safety is another reason smaller businesses are using fleet management solutions. They make it easy to manage access control so that unauthorised operators are unable to make use of their machinery, and also allow management to track driver and user behaviour. “In this way, they know who has been making use of their machine, for how long, in which way, and where the vehicle is located in real time,” he says.

Navigating the options

With the introduction of so many new products, the challenge for businesses is two-fold. Firstly, they need to work out which fleet management system is right for them, and secondly, they need to learn how to use that system as effectively as possible.

Fleet Team believes good fleet management is about more than just deciding what assets to buy

Fleet Team believes good fleet management is about more than just deciding what assets to buy

According to consulting partner Fleet Team, good fleet management is about more than just deciding what assets to buy. It is also about being aware of when those assets are likely to reach their use-by date, as well as putting metrics in place with the goal of achieving excellence across an entire organisation.

“As a brand-independent company working with large clients, large fleets and large geographic footprints, our goal is to make managing fleets easier for the client,” says Douglas Riddle, president of Fleet Team. “We start our implementation with the existing vendor if the client desires us to do so. In most cases, baseline data isn’t available to compare against to see how the current vendor is performing – so we start with the client’s recommendation.”

“On day one, we focus on improving the current system for the client’s benefit versus blowing the old one up for our benefit. If changes need making, we’ll learn quickly as invoices flow and data becomes available. We can work with vendors on continuous improvement and only implement change if we, and our client, do not see desired improvements.”

Fleet management as part of the ‘New Normal’

Stuart Hitchens of Linde Materials Handling is quick to point out that “sales of fleet management has not been affected by COVID in a negative way at all. If anything, it has caused an increase of sales”.

Now that the disruptive effects of the pandemic are largely behind us, and those businesses that experienced a surge in online demand have this new technology in place, it’s difficult to imagine them turning their backs on it and returning to the way they did things pre-pandemic.

In other words, for these organisations and many more, fleet management is set to become part of their ‘new normal’. More broadly, around the globe, it is set to continue to contribute to the safety and efficiency of materials handling operations.

Mentioned solutions can also be seen in this dedicated Virtual Showroom.

For this report we interviewed the following industry specialists: