An innovative safety device to protect operators of stand up industrial trucks against accidental rear-ward collisions with racking systems. |

Canada's Department of National Defence, which supports the Canadian Armed Forces, has adopted The Backbone® for Reach Trucks to protect its standup forklift operators from underride accidents.The DND has internally designated The Backbone as the "Bow Handle", undoubtedly because of its resemblance to an archery bow. But, regardless of the name, it still performs the same critical safety function when installed on your reach trucks and standup forklifts.

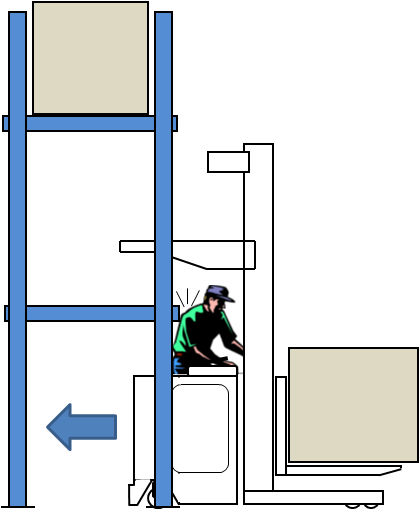

Standup forklift underride can occur when a horizontal rack beam can penetrate the operator compartment. If there are no pallets or stock on the floor, and no bumpers at the height of the overhead guard, the forklift is free to keep backing up, crushing the operator between the rack beam and the front of the compartment. You can see an illustration of an underride accident in the video below.

In a 2008 report, the American Society of Mechanical Engineers (ASME) stated that "greater than 50% of . . . 3,000 accidents studied involved a collision between a stand-up forklift and a stationary object, resulting in . . . 700 serious injuries and 22 deaths . . . of operators."

To prevent forklift underride, you can take these actions:Adjust the rack shelf heights so the forklift body or overhead guard strikes the rack in the event of contact.

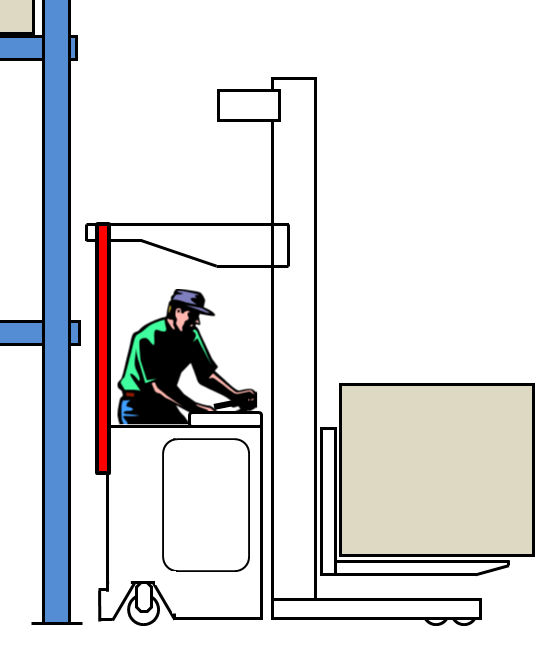

Install a barrier on the floor, such as a curb or floor level shelf so that the bottom of the forklift strikes the barrier.But often, these actions are impractical. The authors of the ASME report concluded that additional forklift guarding, such as rear vertical posts extending from the forklift body to the overhead guard, will prevent injuries associated with horizontal intrusion collisions.

Lakeport Metalcraft Inc. has been manufacturing

The Backbone® Safety Bar for Reach Trucks & Standup Counterbalance Trucks since 2011. The Backbone

® is fully compliant with the ANSI B56.1 Standards, offering protection against collisions up to 1.6 km/h.

Standup Forklift Underride |

|  Standup Forklift with Rear Guarding |

|

For more information, contact:

Norm Nopper, President

Lakeport Metalcraft Inc.

Manufacturer of The Backbone® Safety Bar for Reach Trucks

Direct Line: 416-587-5809

Send an email