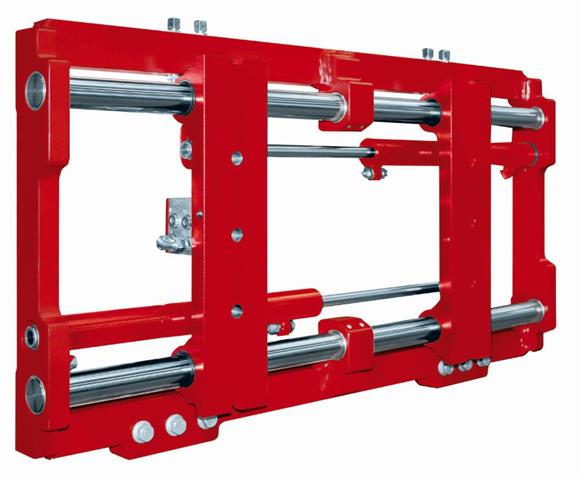

Shaft-guided Fork Positioner 6-25G: the new G-Series for ISO Class 4 is characterized by robustness as well as lowest operation cost (TCO). |

To enhance productivity we need our forklift truck fleets to perform in the most reliable way, limiting all possible downtime stops due to maintenance.

And this is clear at the purchasing moment: also the product Total Cost of Ownership (TCO) has to be taken into consideration.

Starting from the attachment project phase the Bolzoni Auramo and Meyer Engineers focus both on the attachment main function and on the technical features that will grant limited maintenance, fixed and long intervals and low energy consumption. This to get a reliable attachment, that enhances productivity.

What is the Total cost of ownership (TCO)? It is the purchase price of an asset plus the costs of operation within its overall product life cycle.

"An analysis revealed that the costs of operation for a forklift attachment over a period of five years are often relevant.'' says Mr. Mathias Krämker, Key Account Mngr at MEYER GmbH.

"Whilst TCO for forklifts are being calculated and considered, this is not common practice for forklift attachments as yet." This imponderability results in risks especially in fleet operations and full service leasing projects.

BOLZONI AURAMO and MEYER offer forklift attachments which are characterized by low operation costs - a considerable advantage for fleet operations and full service leasing projects.

The shaft-guided Multi Pallet Handler Series G is the sole design with a closed guide system, with complete automated lubrication system for all functions. |

|

Especially the shaft-guided fork positioners,

multi-pallet handlers with hard-chromed bars and high performance bushings distinguish themselves compared to competition by several USPs such as robustness, synchronous fork travel, clean operation and lowest maintenance effort.

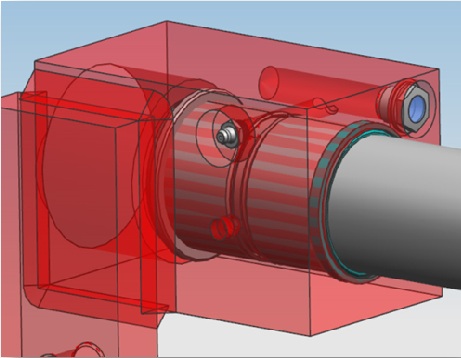

Multi Pallet Handler detail of the sideshifting autolubrication system. |

Thanks to the omission of interim greasing, downtime and labor costs can be reduced. The greasing intervals are extended up to 2000 hours of operation, obtaining an increased efficiency on the logistic processes.

"The shaft-guided system has been applied world-wide successfully since more than 25 years - even under hardest environment conditions'' says Mr. Mathias Krämker.

"MEYER is the sole supplier offering a complete

automatic lubrication system for multi-pallet handlers: both in the sideshifter and in the guide system for the forks.'' adds Mr. Krämker.

This solution contributes significantly to reduce the TCO for these attachments:

Multi Pallet Handler detail of the arm carrier autolubricating system. |

- extended service- and greasing intervals adapted to those of the forklift trucks

- extended lifetime of wear parts reducing maintenance costs

- no interim greasing reducing downtime and effort

- reliable operation especially for multi-shift and fleet operations

- highest energy efficiency due to lowest friction resistance

- avoidance of both oversupply as well as lack of grease and the application of wrong grease

For more information on Bolzoni Auramo products, please visit

www.bolzonigroup.com,

send us an email, or contact the

nearest Bolzoni Auramo representative.

_____________________________________________________________________________

Bolzoni Auramo is a Bolzoni Group brandBolzoni Auramo is a market leader in the production of forklift truck attachments, forks and lift tables. The company has manufacturing plants in Italy, Germany, Finland, America and China and through its network of direct branches and independent dealers covering all continents it is able to satisfy all market requirements.