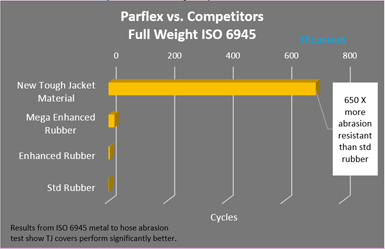

Abrasion resistant hose with 650x the resistance of rubber hose |

We have to buy into the philosophy that all accidents are preventable to make work places safer. Components like hoses with higher levels of reliability and durability equal less failures which, in turn, equates to less accidents. Parflex

TOUGHJACKET™ hydraulic hoses, designed to withstand the strains of large-scale, heavy-duty applications, feature low length change under pressure and special Parker-formulated polyurethane jackets to meet industry requirements for highest abrasion resistance, exceeding the abrasion resistance and durability of rubber hose by 650 times.

ISO 6945 Abrasion Hose Test for TOUGHJACKET hoses |

|

Often materials being transported on forklifts shift in transit, coming in contact with the mast and the hydraulic hoses on the mast. Our customers have indicated this is a major reason for hose failure. Installing a hose with a superior abrasion resistance will extend the life of hoses in the application.

These compact and light-weight hose 563TJ hydraulic hose series offers the best change in length characteristics at +/-1%. This makes it an ideal solution for boom or cable track applications where long lengths are required because abrasion and length change are the biggest contributors to hose failure. The SAE acceptable change in length specification is +2% to -4%. Most hoses shrink at least 2% in a constrained environment which can be disastrous for the hose and cable tracks. If 100 feet of hose is run in a boom, it must accommodate for the extra four feet of hose that will be required due to shrink or run the risk of the hose pulling the fitting off the hose or destroying the cable track.

TOUGHJACKET hoses are up to 40% lighter than competitor's products which means less counter weight, more payload and the ability to lift farther/higher. Its small O.D. makes routing easier in cable tracks and the ability to bond the hose enables the customer to easily pack and manage more elements per track or even eliminate the track. Twin or multi-line configurations are available to further reduce abrasion and/or prevent tangling.

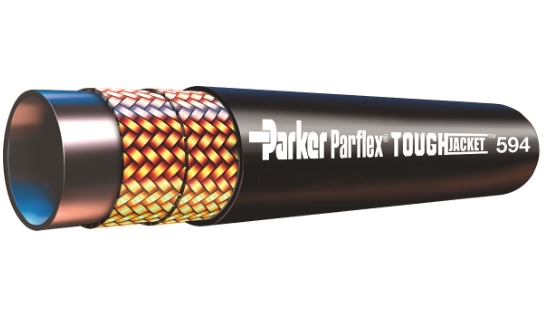

4,000 psi hose for hydraulic applications |

| |  Bonded hose reduces damage from abrasion |

|

The new hoses are available in four series, in sizes from 1/4" I.D. to 1" I.D. Key distinctions and performance criteria by hose series include:- 560TJ: Meets SAE 100R1AT, MSHA. Lighter and smaller than 100R1AT with longer lengths.

- 563TJ: Meets SAE 100R17, MSHA. 3,000 psi constant working pressure. Lowest length change under pressure (+/-1%). Smaller O.D. and up to 42% lighter than comparable 100R17 hose.

- 590TJ: Meets MSHA, and 1/4" through 1/2" ABS approved. Two-wire strength, one-wire construction for improved bend radius.

- 594TJ: Meets SAE 100R19, MSHA. 4,000 psi constant working pressure. Four-spiral wire hose performance in a high tensile, two-wire braid construction.

For information about maintaining over-the-sheave hoses and tips for proper installation, download our latest whitepaper here:

"Step-By-Step Maintenance Guide for Mast Hose" 8 Tips for Mast Hose Maintenance - Parker Whitepaper |

|

Parker Hannifin CorporationParflex Division

1300 N Freedom Street

Ravenna, OH 44266 USA

Phone: +1 (330) 296-2871

Fax: +1 (330) 296-8433

Website: promo.parker.com/promotionsite/toughjacket/us/en/homeAbout Parker

Parker's engineering expertise spans the core motion and control technologies - Aerospace, Climate Control, Electromechanical, Filtration, Fluid & Gas Handling, Hydraulics, Pneumatics, Process Control and Sealing & Shielding. The Parflex Divisions specializes in solutions for extreme applications. Our commitment to our customers is to manufacture products that improve their bottom line by building components with longer life spans, that speed up installation and reduce warranty and service issues in the field.