The HAWKER FLEX battery is essentially maintenance-free. |

The HAWKER FLEX and FLEXPAK Thin Plate Pure Lead (TPPL) batteries represent the latest addition to HAWKER's comprehensive line of battery solutions for today's operations. Suitable for a variety of light-duty and medium-duty applications and essentially maintenance-free, HAWKER FLEX and FLEXPAK batteries provide superior flexibility and allow for frequent recharging. The battery cycle life increases exponentially with more frequent plug-ins.HAWKER is the world's largest industrial battery manufacturer. Their broad range of power solutions can be tailored to meet the specific requirements of any customers' operations. HAWKER's newest battery systems, FLEX and

FLEXPAK, provide a range of motive power batteries (consisting of either 2 volt cells or monoblocs) that offer opportunity charging with no battery changing and practically no maintenance. This provides significant operational benefits at a lower cost of ownership compared to traditional flooded, gel, or air mixed batteries.

Virtually Maintenance-Free BatteriesToday's industrial operations are moving faster than ever. HAWKER's FLEX and FLEXPAK batteries can practically eliminate routine maintenance efforts and improve a company's bottom line. There is no need to water these batteries, and corrosion issues have been eliminated. Shorter recharge times mean quicker battery availability and operators only need to schedule one full charge and equalization per week.

Superior Flexibility for Opportunity Charging ApplicationsHAWKER's FLEX and FLEXPAK batteries provide exceptional flexibility for operators. These batteries can be used whenever needed and can be recharged when time allows - during breaks or at the end of the shift. Additionally, the FLEX and FLEXPAK batteries can even be put back into service before they are fully charged. They're the perfect power source to an opportunity charge application and will go from 40-80% state of charge within one hour with the appropriately sized HAWKER FLEX charger. All FLEX and FLEXPAK batteries are equipped with low voltage alarms (LVA) to automatically assist by alerting the user when their battery should be charged.

Combining advanced battery design technology with robust materials and construction, HAWKER FLEX and FLEXPAK batteries provide the flexibility to reduce operating costs associated with standard flooded batteries by being essentially maintenance-free.

"We are very excited about the value HAWKER's FLEX Thin Plate Pure Lead batteries provide users by enhancing opportunity charge applications," said Dean C. Portney, HAWKER's Vice President of Sales and Marketing.

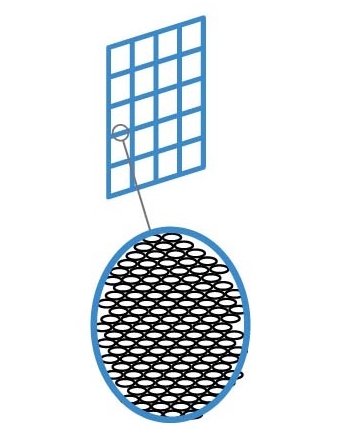

"Deliverable benefits include not having to water these batteries, being able to return more amp hours in the same charge time, and only having to equalize two hours weekly."TPPL's Pure Inside StoryThe key to HAWKER's Thin Plate Pure Lead (TPPL) battery design is the pure material and smart design. TPPL batteries use a thinner grid design of high-purity lead (as compared to the traditional cast lead calcium grids used in conventional sealed lead acid batteries.) The TPPL design results in increased plate surface area within a battery - and that means more available power.

Highlights of the HAWKER TPPL batteries include:- Pure lead crystallography and pure fine grain structure makes the grid far more resistant to corrosion.

- Pure lead antimony grids with the same design life can be much thinner than cast lead calcium grids [Pb-Ca] or lead alloy grids [Pb-Sb].

- Very low internal resistance results in higher charge acceptance.

According to Portney, TPPL technology delivers additional inherent advantages to their FLEX and FLEXPAK batteries.

"TPPL technology stands up better to high rate discharging, has less resistance, and accepts a charge easier than flooded batteries at a fraction of the cost of lithium," he said.

"And, the plates are 99 percent recyclable." HAWKER FLEXPAK batteries include an on-board charger for light-duty applications. |

| |  This artistic rendering shows the fine grain structure of the TPPL grid. |

| |  HAWKER offers several approved chargers for use with FLEX and FLEXPAK batteries. |

|

HAWKER FLEX and FLEXPAK Battery BenefitsHAWKER's FLEX and FLEXPAK batteries feature a superior quality microporous glass mat separator with high electrolyte absorption and stability to enhance cycle capability. Positive and negative plates are low impedance, high corrosion-resistant thin plate grids.

The FLEX and FLEXPAK batteries offer optimized cycling performance and rapid recharging that conventional lead acid batteries (gel or flooded) simply cannot. When used with a HAWKER approved charger, the HAWKER FLEX and FLEXPAK batteries offer a wide range of benefits:

- High energy throughput - up to 300% of C6 per 24 hours for monoblocs and 160% for 2 volt cells

- Long maintenance-free life cycle - up to 1,200 cycles at 60% DoD for monoblocs and up to 1,500 cycles for 2 volt cells at 60% DoD

- Extreme shock and vibration resistance

- Environmentally friendly

- Minimum gassing: ideal for use in shops, public areas, and sensitive manufacturing areas

- Recyclable

- Ideal for multi-shift operations

- Short recharge times - 40-80% state of charge in 35 minutes for monoblocs and 40-80% state of charge in 1 hour for 2 volt cells (with a HAWKER approved charger)

- Ideal for partial state of charge operations with one full charge and EQ per week

- Ideal for opportunity charging

- Works very well in cold storage

- Long shelf life (up to 2 years at 77°F)

The Ideal Charging PartnersThe HAWKER FLEX

™ and FLEXPLUS

™ battery chargers optimize cycling performance and reduce recharging times. These three modular high-frequency, smart charger brands are ideal for use with HAWKER's TPPL batteries: FLEXPLUS MOD3, FLEX MOD3, and LIFETECH

™ MOD1C.

Well Suited for a Variety of ApplicationsThe HAWKER FLEX and FLEXPAK batteries are well suited for all types of light-duty and medium-duty applications. This includes: pallet trucks, industrial utility vehicles, automated guided vehicles (AGV), floor care/cleaning machines, shuttle personnel carriers, and narrow aisle fork trucks.

For more information on HAWKER or their FLEX and FLEXPAK batteries, call 1.877.7HAWKER to speak with a HAWKER representative in your area.HAWKER Kendra Carter-Mansfield

Director of MarketingP: +1 800-238-8658

E: send an email

W: www.hawkerpowersource.comABOUT HAWKER

With more than 85 years of motive power experience and innovation, HAWKER offers a complete line of battery and charger motive power solutions. HAWKER power solutions are designed to reduce environmental impact, lower operational costs, increase productivity, and improve customer operations. As a single-source manufacturer, HAWKER is equipped to assess and design complete power solutions to enhance each customer's operation and optimize productivity, improve efficiency, and minimize cost. HAWKER's exclusive "Harness the Power" on-site assessments analyze operations and provide specific customized solutions for improving material handling productivity. These assessments address all aspects of motive power: maintenance, operational costs, productivity, safety, and electrical consumption and demand.