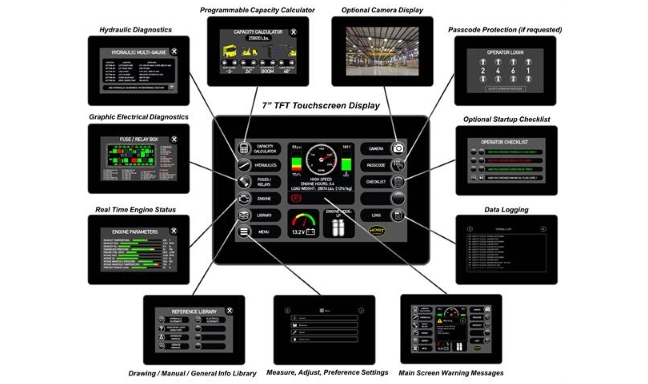

Display provides all necessary information right at the operator's fingertips |

EAST CHICAGO, Indiana, January 19, 2017 - With an updated control layout featuring the new, interactive "Smart Screen Technology" and enhanced capabilities, the FR Series is now even more productive and user friendly than before.The larger, higher resolution display not only includes all of the gauges and indicator lights, but also provides a wealth of operational, diagnostic, and service/support information right at the operator's fingertips. With the touch of a button, the operator can determine safe working loads, do diagnostics on all fuses, and access the "reference library", just to name a few.

Additionally, all individual engine fault codes are now displayed as full text message warnings. Gone are the days of counting check engine light flashes. The updated system eliminates the need for any engine diagnostic tools.

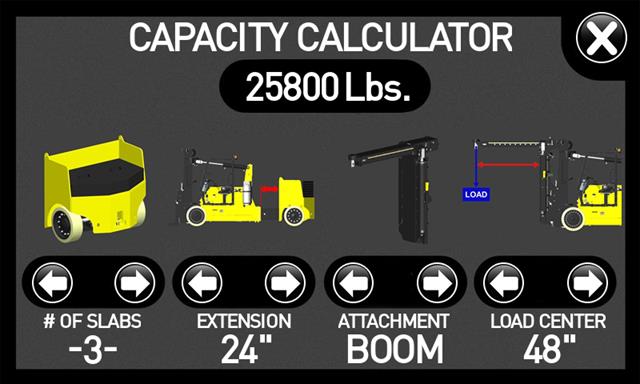

New live action Capacity Calculator can determine safe loads in real time |

| |  Improved graphics and a clear layout make the new display screen more user friendly |

|

The 4-position rotary RPM switch and traditional rocker switches have also been replaced by a pushbutton keypad module. No longer limited to preset positions, RPMs can now be fully adjusted within the entire engine range to best suit the task at hand. Keypad pushbuttons feature indicator lights and are fully weather resistant with an IP67 rating.

For more information on the

FR Series, the new, interactive Smart Screen Technology and Hoist cushion tire forklifts, please contact Hoist Liftruck at +1 708.458.2200 or

send an email.

Hoist Liftruck Mfg. Inc.

P: +1 708 458 2200

E: send us an email

W: www.hoistlift.com

SF: Hoist ShopFrontABOUT US

The BIG TRUCK experts, Hoist Liftruck is a U.S. manufacturer of high-capacity liftrucks ranging from 7 to 57 tons. From heavy-duty cushion tire and pneumatic forklifts to container handlers and reach stackers, all of our liftrucks are 100% made in the USA. Each of our liftrucks are 100% made in the USA thanks to our vertically integrated factory and partnership with domestic vendors. More than 75% of the material on each of our liftrucks is manufactured in-house, including chassis, steer axles and masts, with the remaining sourced from reputable U.S. vendors such as Cummins and Dana. Our dedicated team of professionals strive to provide comprehensive customer service from initial contact to service and parts support in the field. Custom parts and components that are not readily available can be machined and delivered from our factory in less than two weeks.