Convert to Electric with EnerSys |

EnerSys® has helped customers switch more than 5,000 forklifts from Internal Combustion (IC) to electric power since 2008,1 potentially saving them millions of dollars by eliminating the need for fuel. Offered exclusively by EnerSys, the Convert to ElectricSM program (C2ESM) is the material handling industry's first and only program dedicated to helping forklift fleets convert from IC to electric-powered trucks.There are numerous benefits of converting:Significantly reduce fuel and operating costs: Electric forklifts deliver the lowest cost fleet compared to liquid propane, diesel, gasoline or fuel cells. Companies that convert from IC to electric forklifts reduce operating costs in three ways:

- Fuel: Since 40 cents of electricity performs the same work as $2.50 of propane, customers annually save $6,300 on fuel per truck.2

- Maintenance: With fewer parts to repair, electric forklifts cost up to 40 percent less to maintain.3 If using opportunity or fast charging, there's no need to change batteries and no equipment to maintain. Today's electric forklifts offer new intelligence capabilities like wireless monitoring devices to tell operators when batteries need charging, watering and equalization. Battery and charger systems also allow managers to track how each forklift and battery is performing. These systems record minute-by-minute energy throughput, providing detailed information to help managers improve overall fleet performance.

- Operations: The C2ESM program features Zero Battery ChangeSM (ZBCSM) solutions from EnerSys®. These eliminate the need to change batteries and allow trucks to run all day on one battery. Drivers simply charge during regularly scheduled breaks. No battery room is required. With no tanks to change and no need to change batteries, companies can reduce labor costs by $75,000 annually.4 In addition, there is no need for racks or a central battery room, and battery inventory can be reduced by 50 percent or more.

No extra trucks, batteries, change equipment

Reduce greenhouse gas emissions: Using electricity to power forklifts results in the lowest well-to-wheel greenhouse gas (GHG) emissions of any forklift fuel.

5Maintain or even increase forklift performance: Electric forklifts perform as well as IC trucks in critical performance metrics like right-angle stack, lift and travel speeds and turning radius. Because electric trucks work in a variety of conditions, climb ramps and cross uneven pavement, they are an excellent choice to replace indoor and outdoor IC forklifts.

Converting from Internal Combustion to ElectricConversion is easy. When the forklift's lease is up or it has met the end of its useful life, it can be replaced with a model engineered from the ground up to use electricity. As part of the C2E

SM program,

EnerSys specialists use advanced modeling to analyze the customer's operations and energy usage and design a custom battery and charger solution that maximizes savings for current and future needs.

Battery and Charger Solutions Opportunity ChargingZero Battery ChangeSM (ZBCSM), often referred to as opportunity, rapid and fast charging, revolutionized electric forklift fleet management.

With ZBC, there is no need for spare battery storage, handling and changing equipment, freeing up valuable warehouse space. Productivity is improved and potential injuries are avoided, as forklift operators do not need to swap out heavy batteries.

Traditionally, forklift batteries are sized to allow for one daily cycle - defined as eight hours of work, eight hours of charging and eight hours of rest. PSoC allows a battery to be charged many times during a shift, allowing a battery to last one or more shifts.

The following batteries and chargers are ideal for opportunity charging applications:

IRONCLAD® batteries by EnerSys feature a square, tubular plate design that exposes more surface area to the electrolyte, delivering higher sustained voltages and work capacity than round or flat plate designs throughout the discharge cycle.

IRONCLAD Loadhog battery |

The IRONCLAD® Loadhog® battery is a proven, high-performance battery delivering brute strength and staying power. Loadhog

® batteries were the first to pack 100 amp-hours of capacity into a standard 85 amp-hour compartment. That's 18 percent more capacity than similarly sized conventional batteries - more than enough to keep running through the toughest shifts.

-more-

As part of the IRONCLAD

® battery line, the Loadhog® battery delivers higher voltage levels throughout discharge than standard flat plate or round tube battery designs. When installed in a DC forklift, the benefit of higher voltage is straightforward: faster drive and lift speeds. Higher amp-hour capacity ratings ensure the forklift runs long into the shift day, maximizing productivity.

In AC forklifts, the Loadhog

® battery sustains consistent run and lift speeds until the battery reaches the maximum discharge level. This consistency is possible because the AC motor offsets a battery's normal voltage drop during discharge by drawing increasingly more amps. Because the Loadhog

® battery sustains higher voltages throughout the shift, combined with its higher amp-hour capacity ratings, it will provide longer run times in an AC forklift compared to a flat plate or round tube battery design.

IRONCLAD Superhog battery |

IRONCLAD® Superhog® batteries by EnerSys offer the industry's highest capacity - up to 30 percent more run time than conventional batteries. They provide the fastest runs and quickest lifts for the most demanding industrial and warehousing applications. The supercharged Superhog

® battery delivers consistently higher sustained voltages to maintain optimum travel speeds, lift quicker, and last longer into the shift, reducing heat and strain on the forklift's electrical components.

Designed with IRONCLAD

® square tubular plates, Superhog batteries provide increased work capacity and higher sustained voltages throughout the discharge cycle.

While the Superhog

® battery boosts productivity, it also cuts costs. Superhog

® batteries decrease expensive forklift maintenance because the higher sustained voltage and lower amp draw reduces heat and strain on the forklift's electrical components. The forklifts then perform better during the shift and run longer before change-out; fewer change-outs mean greater productivity.

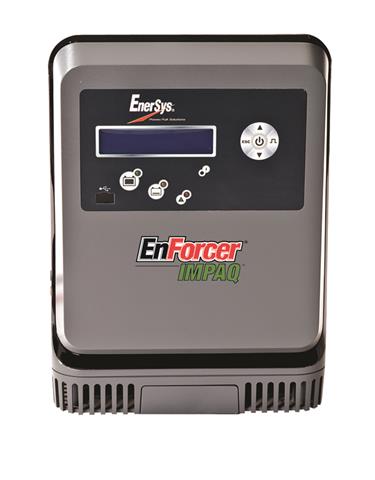

EnForcer IMPAQ |

EnForcer® IMPAQ™ high frequency modular chargers offer intelligent charging with advanced efficiency and the flexibility to maintain peak efficiency. Whether free-standing or wall-mounted, IMPAQ

™ modular chargers are the most compact

EnerSys chargers ever, representing a best-in-class, high frequency charging solution for all applications of material handling equipment, automated guided vehicle systems, cleaning machines and industrial electric vehicles.

Charger modules automatically switch on and off based on the charge cycle requirements. Should a module develop a minor fault, the charger bypasses the module for continued operation without interruption.

IMPAQ

™ chargers include several charging profiles, from standard flooded and Valve Regulated Lead Acid (VRLA) to cold storage and opportunity charging in multiple configurations.

EnForcer IMPAQ+ |

EnForcer® IMPAQ™+ modular chargers use the exclusive EnerSys IONIC

™ charge profile to continually diagnose battery condition throughout charging for the most effective and efficient process possible.

Fast ChargingFast or rapid charging refers to applying charge rates between 25 and 50 amps per 100 AH of the battery's rated capacity. When applied to batteries designed to

only accept standard charge rates, fast charging may cause excessive heat. However, that heat can be managed with an appropriate battery design and smart charging techniques.

Like Loadhog

® and Superhog

® batteries,

Express® batteries are designed with square-tube technology. Only Express

® batteries are engineered and manufactured specifically for fast charging, superior performance and long life, with the ability to easily handle "extra heavy" days.

With heavy-duty components and factory-installed watering systems, Express

® batteries run cooler, last longer and deliver more capacity than other fast-charge batteries. Express

® batteries deliver maximum productivity, allowing forklifts to run longer, harder and faster between charges. The maximum thermal management and charge acceptance design provides up to 18 percent more amp hour capacity compared to flat plate, fast charge batteries.

Express® eMAX HF® fast chargers can charge 12- to 80-volt industrial lead acid batteries at currents of up to 640 amps, bringing a battery from 30 percent to 80 percent state of charge in approximately 1.5 hours, depending on battery size.

Packed with the latest innovations in high frequency fast charging, eMAX HF

® fast chargers have been engineered to provide the highest level of efficiency in an amazingly compact size. With its lightweight space-saving design, they make installation easy and inexpensive. Fast charging saves money by eliminating the need for battery changes so that multi-shift operations are able to run on one battery. This translates to higher labor productivity, energy savings and more manufacturing floor space for a quick return on investment.

Next Steps?Your

C2ESM program begins with a free consultation, including an introductory on-site visit, discussion about operational needs and current fleet usage. Schedule a free C2E

SM consultation today by

emailing convert2electric or

calling toll-free 855-421-4200.

Visit www.convert2electric.com. ABOUT ENERSYS®

EnerSys, the global leader in stored energy solutions for industrial applications, manufactures and distributes reserve power and motive power batteries, battery chargers, power equipment, battery accessories and outdoor equipment enclosure solutions to customers worldwide. Motive power batteries and chargers are utilized in electric forklift trucks and other commercial electric powered vehicles. Reserve power batteries are used in the telecommunication and utility industries, uninterruptible power supplies, and numerous applications requiring stored energy solutions including medical, aerospace and defense systems. Outdoor equipment enclosure products are utilized in the telecommunication, cable, utility, transportation industries and by government and defense customers. The company also provides aftermarket and customer support services to its customers from over 100 countries through its sales and manufacturing locations around the world. |

EnerSys

t: +1 610-208-1991

e: send an email

w: www.enersys.com- http://convert2electric.com/expertise/

- Energy prices based on national averages available at U.S. Energy Information Administration.

- Electric Power Research Institute (EPRI)

- Savings calculation based on national average energy prices available at U.S. Energy Information Administration

- U.S. Department of Energy