Despite 20 years of sustained economic growth the cost of hiring a forklift has actually fallen. |

The Fork Lift Truck Association (FLTA) is warning forklift users to get the right forklift hire contract - and not the cheapest one - for safety reasons.

The FLTA's recent research shows that contract hire prices are lower than they were 20 years ago and the association is concerned that forklift suppliers could be cutting corners to provide forklifts at low prices.

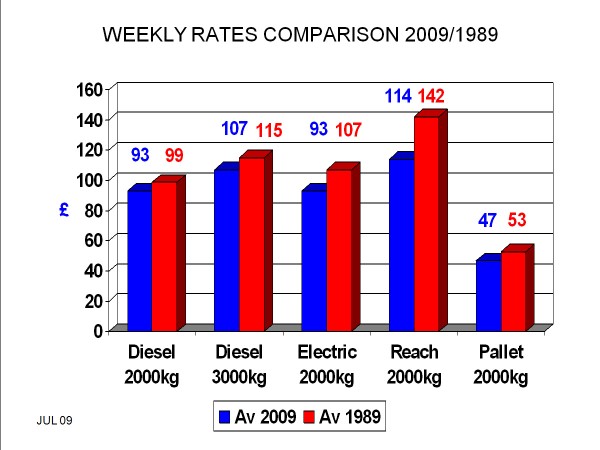

Its research reveals that average weekly forklift hire prices in 2009 are 17.8% lower than they were in 1989, before adjustments for inflation. The weekly hire rate for a reach truck has dropped from GBP142 (USD202.66) to GBP114 (USD162.70) and a 2.0 tonne electric counterbalance forklift, which cost GBP107 (USD152.76) a week to hire in 1989, or GBP191 (USD272.70) in today's money, now costs just GBP93 (USD132.80).

Comparing the forklift and automotive industries, the FLTA says that the industry norm for the levels of usage in contract and lease hire arrangements differ massively.

In the forklift sector, 40 hours a week is commonly assumed to represent a single shift. This equates to over 2,000 operating hours a year and puts significant strain on forklift components and suppliers.

By comparison, a similar level of usage in a contract rental car, even at an average speed of 30mph (48kmh), would give an annual mileage in excess of 62,000 miles (99,779km). This usage would be viewed as extreme, incurring a penalty and requiring service every two to three months.

The FLTA says it is therefore reasonable that 40 hours per week should be considered as "extended hours" for a forklift, or even a double shift.

"The current recession has led some forklift users to cut their level of preventative maintenance by as much as 50%. With forklifts already under strain and given the intensive workload demands on them, taking such drastic action could place a customer at risk of falling foul of the law," FLTA president David Ellison warns.

Under the Provision and Use of Work Regulations, a forklift user has a legal duty to ensure a forklift is always in good repair. The FLTA advises that as a minimum, a forklift should be subjected to "a sound system of daily or pre-shift checks" and a regular schedule of preventative maintenance that meets the manufacturer's recommendations and is compatible with usage.

"In an unsteady marketplace, users need to be alert to potential pitfalls. If a deal looks too good to be true, it probably is," Ellison says.

He adds that a significantly reduced price could indicate a significantly reduced level of service provision, thus compromising safety.