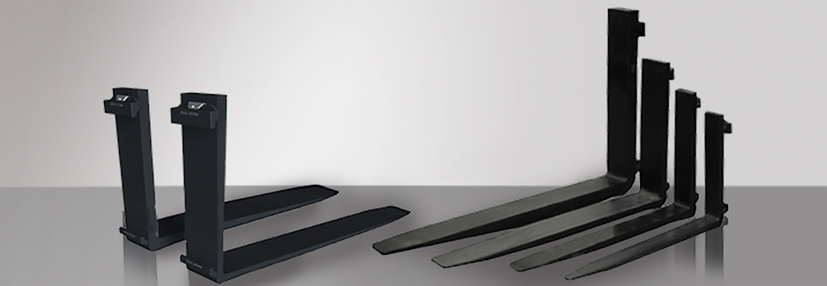

Bolzoni Group produce and distribute a wide range of forks suitable for any type of material handling.

Bolzoni Group produce and distribute a wide range of forks suitable for any type of material handling.

Every industry faces unique challenges, especially when it comes to lifting and storing heavy duty and oversized loads. Operators, working with large and bulky loads, are aware of the hidden dangers in the handling of these materials, which can lead to severe unexpected consequences, both in terms of safety and efficiency.

Boats, huge containers, logs, timber and steel bars; all of these products need reliable handling equipment, ensuring safe and efficient operations through the whole material handling process.

To support heavy duty industries, the Bolzoni Group have now enlarged its fork offering, adding high capacity forks to the range of standard and special forks, to fit all forklift trucks and to face every type of though handling requirement.

Material handling in heavy-duty industries requires specialized and highly customized equipment.

Material handling in heavy-duty industries requires specialized and highly customized equipment.

State-of-the-art forks

To be installed at the origin by OEM's and by the after-market professionals, forks are the basic attachment, fitted as standard on new forklift trucks.

The Bolzoni Group is manufacturing a complete range of forks for lift trucks, construction and agricultural material handling machines, from standard forks in many different capacities, sections and lengths, to special forks.

These are manufactured in a dedicated production plant, where we apply the most advanced technologies and software in fork designing and manufacturing, in order to offer a product that stands out in terms of quality, reliability, and durability.

The range includes:

- ISO2328 standard forks

- Camera fitted forks, with side, tip or front camera with laser, to increase visibility on high shelves

- Non-standard ISO forks, with a wide range of tips and tapers, to optimize operations for all unique handling needs

- High capacity forks, with capacities up to 220 tons, for heavy duty applications.

- Wireless fork scale, lithium ion battery powered, to speed up the weighing process

Bolzoni high capacity forks: the heavier the load the bigger the fork

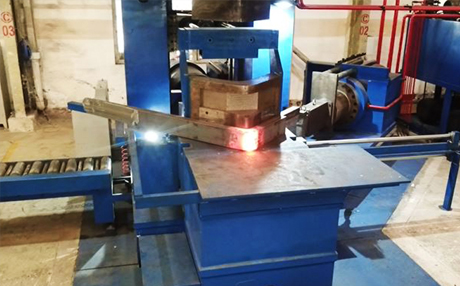

Forks production includes complete heat treatment with hardening and tempering on the entire fork, providing the best quality and reliability characteristics.

Forks production includes complete heat treatment with hardening and tempering on the entire fork, providing the best quality and reliability characteristics.

With a capacity up to 220 tons, the Bolzoni high capacity forks are usually employed for a wide variety of applications such as heavy-duty constructions, lumber yards, in the harbor/railway station handling and in many industries including the mining industry, steel mills and in other fields requiring lifting and handling of heavy and bulky loads.

In order to meet the heavy-duty requirements of these industries, high capacity forks are manufactured with the finest steel material, offering good welding characteristics and strong resistance to wear, and have reinforced fork heel, bended in a multi-phase press mould to ensure the best performances.

These forks undergo the most severe tests required by the market. For the fatigue and static load performance test we employ a very big testing machine (with max. bearing capacity of 300kN). The fork examinations include also the fork’s hardness inspection and the magnetic particle test, performed on all forks welding and heels.

The result is that Bolzoni high capacity fork’s technical features meet and even exceed industry standards. The forks are available in several sections, up to 400 x 200 mm, completing the entire forks range. In addition, forks back height, length and hooking system can be customized.

Bolzoni non-standard ISO forks

The Bolzoni Group forks range also includes a variety of non-standard ISO forks, such as Pin-type forks, Quick detach forks, Peek-A-Boo forks, Gypsum forks, Folding forks, Brass/Stainless steel coated forks, Bolt-on forks, Full taper and polished forks, Drum handing forks and other special designs.

Bolzoni Group has the right fork for any application, with different tips and tapers.

Bolzoni Group has the right fork for any application, with different tips and tapers.

Fork tip can be customized with reduced thickness for special applications, and with various taper shapes: from standard taper to full top/bottom taper and polish or without taper at all.

All forks are produced following the parameters outlined in ISO 2328 and ISO 2330.

For more information on Bolzoni High Capacity forks, get in touch with the Bolzoni Group forks Specialist, send an email and ask for our references on forks, or to organize a demo unit at your facilities.

Visit the dedicated forks section on our web site and contact us, or connect with the nearest BOLZONI, AURAMO and MEYER representative.

Bolzoni, Auramo and Meyer are Bolzoni Group brands.

The Bolzoni Group is a market leader in the production of forklift truck attachments, forks and lift tables. The company has manufacturing plants in Italy, Germany, Finland, America and China and through its network of direct branches and independent dealers covering all continents it is able to satisfy all market requirements.