The World's favourite battery management system, Philadelphia Scientific's iBOS, now has a compact version. The iBOS Basic is priced so that all battery owners can afford to reap the same benefits as the big fleet operators.

Computerised battery management systems are a standard tool in most operations with large volumes of forklift batteries. The iBOS (Intelligent Battery Organisation System) is the best selling battery room technology with over 150 systems installed globally in the last 12 months. In essence it identifies which battery the operator should select next, as well as delivering vital information on battery performance for the manager.

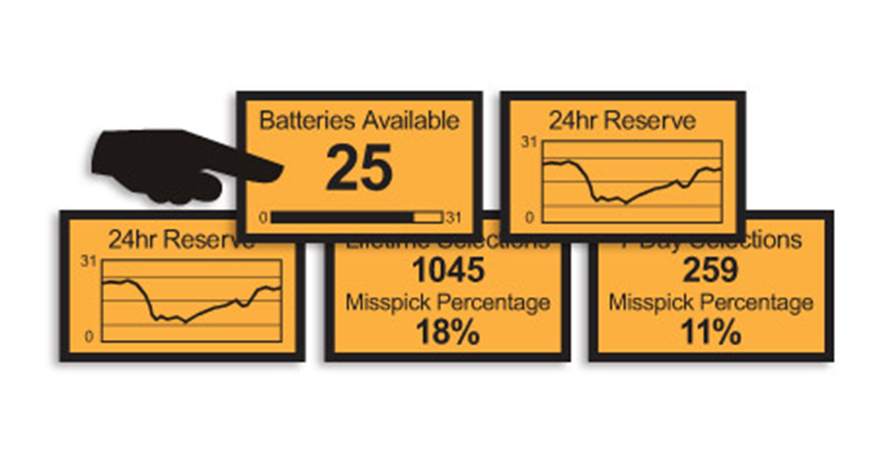

An iBOS Basic interactive display |

The cost and productivity gains from using an iBOS mean that in nearly all circumstances the system

pays for itself within just a couple of months of installation. The iBOS:

- Increases battery life and run times.

Correctly cycling batteries will increase the ability of a battery to retain its charge further into its life.

- Reduces battery change times.

Park the forklift, look at the iBOS display for the location of the next best battery to take, go straight to the battery - no need to examine chargers or follow the manual selection protocol.

- Uses the most efficient number of batteries.

Two shifts, two batteries? Not necessarily - one and half batteries for each forklift may well be sufficient. Because the iBOS is based on end of charge queuing you will maximise the potential of the batteries in the system.

- Is universal to any charger on the market.

The iBOS can be installed on the most basic of chargers or the most high tech, any model from any manufacturer.

- Delivers user friendly information.

Is my fleet working to its maximum capability?

Can I save money on my battery numbers?

For the Basic version the iBOS has been streamlined with a new control box which manages up to 31 chargers in a pool. The new 'brains' of the system provides:

- Out of the box installation.

Just plug and play, no technical knowledge required. Also the only information required prior to ordering is the number of chargers and their voltage.

- Miss-pick alarm as standard.

The operator is alerted when they have taken the wrong battery as they trigger an audible alarm.

- Integrated interactive screen.

The correct battery location and usage information is displayed on a touch screen display built into the control box.

Invest in a battery handling solution from Philadelphia Scientific at the same time as the battery management system and receive a complete package deal. Philadelphia Scientific has a complete range of battery handling equipment for every application, from battery hoists to multi-level changing systems. We can advise you on the best value handling, management and maintenance solution whatever your situation.

If you own, or have a customer that owns, more than one battery per forklift, contact Chris Parkinson,

chris@phlsci.com.au + 61 2 8004 2447 in Australasia and Asia, or David Smith

david.smith@ps-europe.net + 44 1204 467 777 in the rest of the world, and enquire about how we can reduce the cost of owning a battery electric forklift.