With the continuous development of AI and robotics technology, intelligent and automated warehousing has become a key measure to enhance productivity and service experience. From e-commerce to production lines, "intelligent warehousing and logistics" has become an inevitable path and a future battleground. Wellwit Robotics has over a decade of dedicated automation experience as a professional manufacturer of AGV/AMR, and provides OEM and ODM service for clients globally.

Due to the scarcity of land resources and the continuous increase in warehousing costs, as well as the gradual reduction of warehouse operating areas, many companies are faced with the challenge of maximizing warehouse space utilization. In this context, narrow aisle forklifts have become an increasingly sought-after solution for many businesses. Compared to traditional forklifts, narrow aisle forklifts have a smaller turning radius, which can increase storage capacity in warehouses by 30% to 40%, allowing companies to effectively utilize every inch of valuable space.

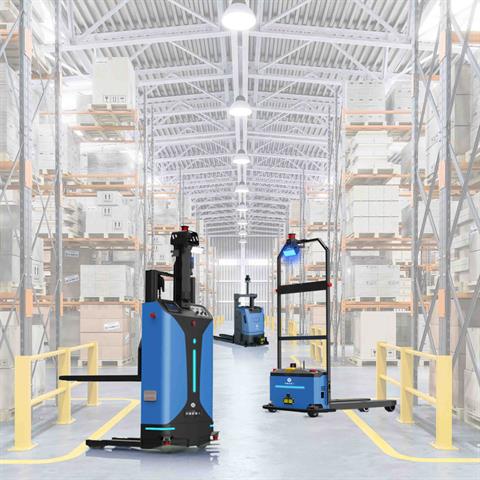

Unmanned forklifts are fusion of the technology of forklift and AGV. With the help of advanced guidance technology, mapping algorithms, embedded vehicle software, and safety avoidance technology, unmanned forklifts achieve automatic guidance, handling, and stacking functions, thereby realizing automated forklift operations. The distinctive feature of these unmanned forklifts lies in their ability to autonomously navigate and perform handling and stacking tasks, making the operational processes more efficient and intelligent.

With the continuous advancement of Industry 4.0 and smart logistics, unmanned forklifts have become essential equipment in the mainstream application scenarios of the logistics and warehousing industry, playing a crucial role in intelligent warehouse management systems. Compared to regular AGVs, forklift AGVs not only perform point-to-point material handling but also enable logistics transportation that integrates multiple production processes. When unmanned forklifts are used for material handling in intelligent warehousing, the handling efficiency can be improved by 2 to 3 times. Moreover, the unmanned forklift can seamlessly integrate with the AGV scheduling system and the e-commerce warehousing WMS system to achieve fast order response.

Specific features of the WMF1000 from Wellwit.

With the increasing demand for automated handling in the industry, the forklift that integrates stacking functionality with automated guided handling has been favored by enterprises in recent years. In the overseas market, our forklift-WMF1000 has been widely acclaimed. It has the following functions: with a navigation accuracy of ±10mm; equipped with advanced 3D vision modules, enabling vehicle and shelf recognition; load capacity up to 1400kg; maximum running speed (full load) of 1.5m/s; maximum lifting height of 3m; fully automated moving and access into 1.2m narrow aisles; the charging time is about 2 hours, but the overall battery life can reach up to 8 hours; enabling 360° rotation around the center. This forklift is also CE mark, making it a powerful, safe, reliable, and energy-efficient product suitable for various logistics, warehousing, and manufacturing industries.

Focusing on ODM/OEM services for warehouse robots is one of the differentiating advantages of Wellwit Robotics. In the future, the forklift industry will evolve towards intelligent, efficient, green, human-machine collaboration, and data-driven management. These trends will continuously drive innovation and progress in the forklift industry, providing better services and support for the development of the logistics industry. Additionally, with the help of technologies such as 5G, big data, Internet of Things (IoT), and cloud computing, unmanned forklifts will not only simply transport goods to designated locations but become multifunctional new intelligent industrial equipment with real-time sensing, secure identification, multiple obstacle avoidance, intelligent decision-making, and automatic execution capabilities.

To find out more, get in contact with us!