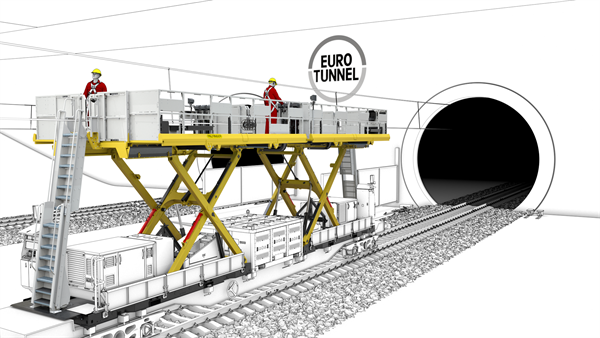

Palfinger's custom PA1500 scissor lift platform |

Palfinger has developed a custom-made PA1500 scissor lift platform for its British partner, GOS Tool Engineering Services, as part of a large-scale order for new service units for the Eurotunnel.

The rail link between London and Paris is used by 20 million passengers a year. Now, 27 years after it was opened, a high-voltage direct current power cable is being installed in the Channel Tunnel to allow an exchange of electricity between Great Britain and France. A risk assessment carried out by Eurotunnel found that the power line was most likely to be damaged by a crane or an access platform during routine maintenance work. GOS and Palfinger Railway were given the task of finding a way of ruling out this risk.

The new PA1500 scissor lifts, developed as a custom-made small series, meet the exacting requirements of the project. The platform has a safe working load of 1.5 T and can work at an inclination of 10 deg. when fully laden. The basket is 6 m long, and the width is adjustable from 2.9 to 4.5 m, giving a maximum working space of nearly 30 sqm.

The platform's modular construction means it can be used on a wide variety of vehicles. By engaging synchronous operation mode, every movement of two scissor lift platforms mounted one behind the other can be controlled simultaneously using a remote control. "The scissor lifts are impressive," comments Carl Jones, director of rail engineering at GOS. "The tremendous engineering quality of the details sets Palfinger apart."

Apart from the PA1500 platforms, the order also includes two PKR 800 railway cranes, six PR 220 cranes including BB 29 and BB 49 baskets, two PA 200 platforms and other equipment.

"GOS knows that we deliver top quality, always focus on solutions and adapt our work to each customer's requirements," says Christian Prantl, head of sales at Palfinger Railway. "A strong partnership and deep mutual trust are the key elements in this project's success."