Product Protector LLC of Eugene, Oregon and Intralox LLC of Harahan, Louisiana won MHI innovation awards at the Modex 2014 show in Atlanta.

MHI received 77 entries in the competition for the 2014 MHI innovation awards. MHI ran its inaugural innovation awards program in 2013.

Judges selected six finalists in each category, and another panel conducted final reviews on the opening day of the four-day Modex 2014 show, which is focusing on exhibits and educational sessions for supply chain solutions.

MHI of Charlotte, North Carolina also sponsors the ProMat trade show, to be held on 23-26 March 2015 in Chicago.

Product Protector LLC Forklift attachment from Product Protector LLC |

Product Protector's patented forklift attachment won for the best innovation of an existing product.

"Normally, when forklifts approach a palletised load, the point of contact is the back of the forks and the lead board of the pallet," according to the company. "This minimal contact area directs all the force of impact straight into the lead board, resulting in broken pallets and damaged products."

The attachment expands a forklift's surface area and redirects the impact to the strongest part of the pallet ? the stringer or the blocks. "By increasing the surface area, it forces the pallet to square up allowing the driver to enter the pallet straight-on, greatly reducing lead board damage," the company says. "This also reduces the risk of rollover since the large pesky wood chips are eliminated."

Product Protector says a recent study by Dr Marshal White of Virginia Polytechnic Institute and State University in Blacksburg, Virginia found that the attachment can reduce product damage by up to 80% and double the life of a pallet.

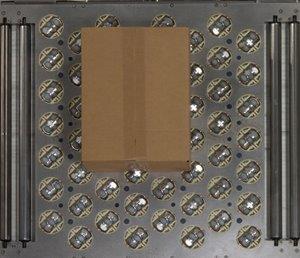

Intralox LLC Omni-Directional sorter from Intralox LLC |

Intralox's patented Omni-Directional sorter won as the best new innovation.

The global provider of conveyance solutions says the sorter can both receive products from any direction and then sort them in any direction at high rates within a compact footprint. Intralox developed the sorter for zone picking applications where items must be sorted to manual picking areas and then merged back onto the same conveyor.

Another application for the sorter involves single-level infeed/outfeed to automated storage and retrieval systems at rates above 1,800 cases or totes per hour.