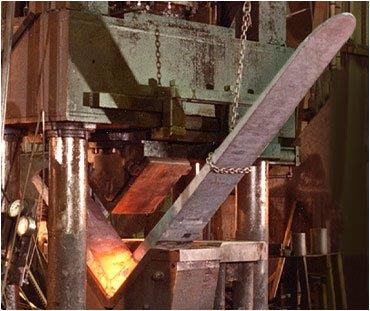

Dyson's fully forged process |

Dyson Corp is resuming the manufacturing of forklift tynes after a market absence of several years.

"Our forklift arms are used in severe-duty applications requiring the highest strength and durability," says Dustin Johnson, sales manager. "Our forklift arms are designed to lift between 25-180 T."

Some former tynes customers encouraged Dyson to get back into the forklift market after a subsidiary of Toyota Industries Corp of Kariya, Japan

acquired preeminent attachments maker Cascade Corp of Fairview, Oregon for about USD759 million on 28 March.

Dyson made tynes for early forklift truck manufacturer Towmotor in the 1930s and was involved in the market until several years ago.

Dyson can produce heavy-duty forklift tynes for materials handling in mining, forestry, heavy construction, steel making and ship container applications. Configurations include coil ram, marine, tapered shank, offset tapered shank, explosive environment and customised products.

Dyson takes billets or blooms and, utilising a 750T. Erie Press Systems machine, forges one-piece forks, blades, heels and upright shanks. Another smaller press is used for the final bend.

In addition to fully forged forklift tynes, Dyson in Painesville manufactures bolts and screws, nuts and washers, rods/studs/pins, construction accessories, specialty fasteners and custom forgings. The weight range of the forgings is 0.5-10,000 lb. (0.23-4,500 kg). Other production equipment includes hammers, mechanical and hydraulic presses, up setters, benders, hot part formers and computer numerical controlled mills.

Joseph Dyson started the business in 1884 with small forgings for various industries. Later, the company developed the capabilities to manufacture larger fasteners and forgings as well as forklift arms for the materials handling industry.

Dyson employs about 100 staff and operates Texas Bolt & Nut Co in Houston, Texas as an affiliate.

Dyson's largest end markets involve forged bolts, nuts, socket head cap screws, lock nuts and construction fasteners for bridge and waterway infrastructures, mining and wind-power generation, Johnson says.