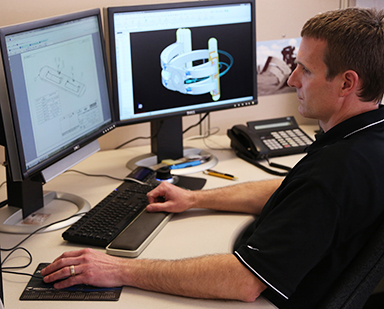

Years of experience and the latest technology give Cascade's team of engineers the competitive edge in roll clamp design. |

Cascade Corporation invented the first convex contact pad for Tissue Roll Clamps more than 20 years ago after recognizing the need for a scientific approach to handle low-density paper. Ongoing research and a culture of continuous improvement has revolutionized the industry and enables Cascade to consistently release innovative attachments and effective damage control solutions for tissue paper producers. Many tissue companies are seeing tremendous benefits by successfully utilizing Cascade clamps.JBT Corporation is a producer of Automatic Guided Vehicle (AGV) systems and other material handling solutions. According to their Marketing Manager Mark Longacre, "The use of Cascade clamps on JBT AGVs has resulted in a measurable reduction in paper damage for tissue customers, with a payback period as low as one year."

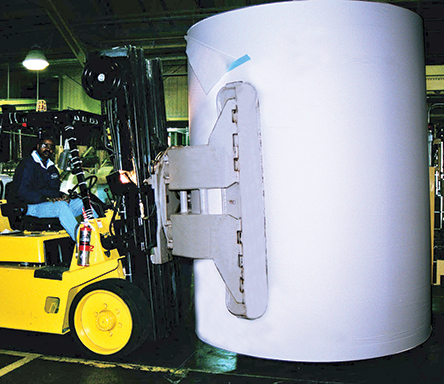

Cascade's Tissue Roll Clamps provide industry-leading solutions with the ideal combination of innovation and technology. |

Cascade Tissue Roll Clamps are all custom Application Engineer Designed (AED) specifically for each user to meet their individual needs. According to Cascade Product Manager Brad Vandehey, "We don't just offer one clamp or pad that fits all. We offer a variety of base solutions, taking the many variables into account, and design customized Tissue Roll Clamps specific to each customer's application." Vandehey goes on to say, "Using mathematical models that fine-tune the pad size, and by calculating the paper density, we invented several unique pad types, with custom shapes and sizes, to meet the demanding needs of the industry. Additionally significant, we provide the expertise to help users choose which pad will be best suited for their requirements."

The pads Vandehey refers to are high-friction

contact pads that hold rolls securely with minimal clamp force resulting in a reduction of roll out-of-roundness and subsequent paper damage. Cascade's pad uses a herringbone pattern that allows the paper to glide and flow over the pad in both horizontal and vertical directions. This unique diamond-patterned surface has been shown to provide the best combination of friction for tissue paper.

A Variety of Pad Types Meets Customer's Individual NeedsSome of the many solutions

Cascade offers today are:

- Single Diameter: Best suited for high-density tissue paper grades, such as industrial toweling. The large surface area of the pad minimizes roll deformation and specialized features that prevent cutting of the tissue. This pad can be used to handle narrow width rolls.

- Double Diameter (with optional flared ends): Best suited for medium-density tissue paper grades, such as paper towel. Optional features reduce cutting of tissue at pad ends. Unique pad qualities allow the paper to transition around the pad without tearing and adapts to slight-to-moderate paper deflection.

- Convex: Best suited for low-density tissue paper grades, such as ultra-soft facial and toilet tissue as well as soft toweling (TAD paper). Features a convex surface that flares out at the end, specially designed to provide a smooth transition during roll deflection. The shape conforms to the surface of the roll, allowing the paper to flow around the pad, which prevents creasing, tearing and cutting into the roll. The hardened wear surface prevents pad wear caused by floor contact.

For more information on

Cascade Tissue Paper Clamps and Pads or to learn about how Cascade products can improve your business,

visit www.cascorp.com or

call 800 CASCADE (227-2233).

Cascade Corporation was established in Portland OR in 1943 and is now the global leader in the design, manufacture, and marketing of materials handling equipment and related technologies. Cascade's advanced damage reduction technology, short lead times, flexible manufacturing, and quality products strengthen the company's position as the premier supplier to the material handling industry. For more company and product information visit the Cascade ShopFront