Forklift IDs are managed in the TagMaster software |

A Texas retailer has solved its own logistical problem around managing automated roll-up doors in a heavily trafficked warehouse, using an RFID-based system.

The company, which has asked to remain unnamed, stores and manages a large amount of temperature-sensitive products at its Texas warehouse. The facility has dozens of freezers and coolers in which the products are stored until they can be loaded onto a vehicle for delivery to stores.

According to a case study published in

RFID Journal, the firm has been challenged with controlling when those doors are opened and closed. An IR-based sensor system caused the doors to open too often, even if a vehicle might not be entering the freezer or cooler, but simply remaining in the vicinity.

The company initially tried a sensor-based system, but that was not reliable.

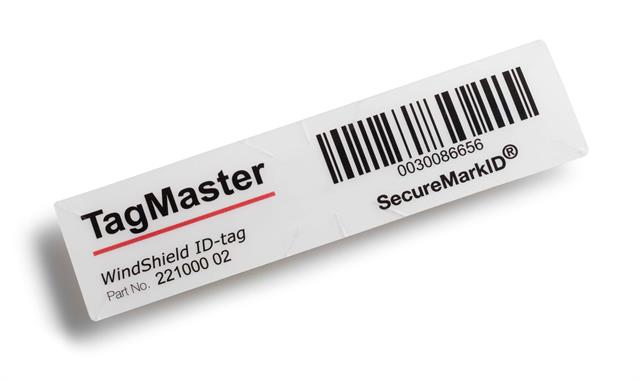

It ended up using a battery-assisted passive RFID solution from TagMaster to pinpoint a forklift's location, confirm a driver's authorisation to enter, prompt the subsequent door opening and store the related data.

The solution involves several dozen LR3Pro RFID readers, one above each door, to receive the RFID transmissions. The readers have logic built into them, with embedded controls to trigger the doors to open when authorised.

The company has TagMaster S1240 BAP 2.45 GHz outdoor-use heavy-duty tags fitted to the front of each forklift. Each tag has a unique ID number encoded to it, which beacons continuously. The tag's ID is linked to the forklift ID in the TagMaster software. In that way, warehouse management can access the software to update authorisation rules for specific vehicles to enter through a given set of doors.

"The main (return on investment) was preventing accidents and increasing safety," says Ali Khaksar, president of TagMaster. He adds that the company is also seeing a benefit in reduced energy cost.

The firm may next opt to expand the deployment to other warehouses.