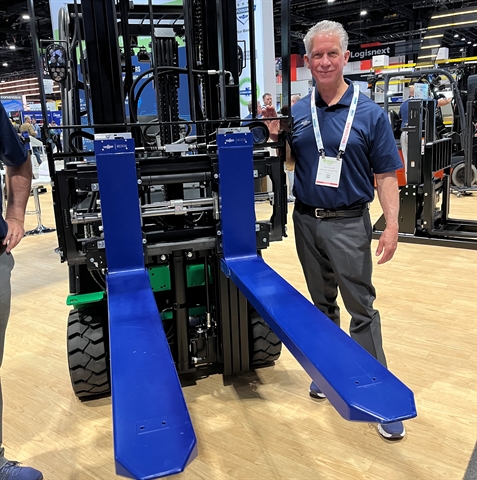

Noblelift North America's Bill Pedriana

Noblelift North America's Bill Pedriana“A totally open-sourced forklift is antithetical to the material handling sector,” states Bill Pedriana, president of Noblelift North America. And yet this is exactly what he was excitedly promoting at ProMat in Chicago in March.

“It’s a radical concept,” he adds.

Indeed it is. A forklift developed by a community with no proprietary ownership of the information and technology, allowing it to be continuously developed by that community to drive down costs, is certainly something quite outside of the norms of competitive business.

But this spirit of collaboration may prove to be the way business is done in the future, according to Pedriana.

The Alpha-50v1.0 open-source forklift will be launched to market in July and will also be available initially with an IC chassis for customers who are not yet ready to embrace electrification, but these can be retrofitted down the track with lithium-ion batteries.

“Alpha is an open source global sustainability project focused on helping the world transition from IC to clean electric power,” Pedriana says.

Noblelift says there are currently more than 10 million internal combustion forklifts in operation globally with an additional million new units purchased each year.

Noblelift hopes to have university programs and other collaborators on the Alpha project work together to drive down the cost of electric materials handling products so they can be accessible.

Subsidised Alpha units will be available to university and engineering programs participating in Noblelift’s open course community at USD19,900 USD.

“Who knows… maybe more industries will follow based on the example we set and put collaboration ahead of competition in the service of their customers and our planet,” Noblelift states of the Alpha initiative.

Collaborate rather than compete

Since taking on the role of president of Noblelift North America in January this year, Pedriana has taken what he refers to as the company’s “culture of collaboration” which has seen it become a leading manufacturer of white label materials handling equipment for OEMs, and stretched it further still.

“There are a lot of companies trying to control the future right now,” Pedriana, who has a 30-plus year career in materials handling, tells Forkliftaction News. “They are still in this competitive mindset.

“But things are happening so fast, you need to give up trying to control and instead put yourself in a position to take advantage of what is likely to emerge which can be partnering with a quick adaptor who will help you find opportunities and adapt.

“Collaboration is being prepared for what is coming.”

For Pedriana this means working as a community for the greater good and achieving business success by “offering quality and the full-service approach” where customers don’t need to go to another company for solutions, rather than competing for the sake of competing.

“I think in 10 years, if we had a snapshot of this,” he says looking around the bustle of the ProMat event, “it could all look like it belongs in the Smithsonian. There will be so much change coming into the supply chain, we won’t recognise it from what we see now. AI will come up with stuff in the future we can’t even imagine now.

“I believe collaboration and less competition is the type of mindset people will win with.”

But not everyone agrees with Pedriana.

Or is customisation the key?

Cascade Corporation's Keith Miller

Cascade Corporation's Keith Miller

Keith Miller, director of Sales Americas with forklift attachment producer Cascade Corporation says customisation of equipment and attachments will become increasingly important to stand out from competition as the market moves forward adding that “70% of what we produce is customised”.

Ziyad Al-Janaby, senior product engineer with customisable forklift cab producer Harris Stolper, says the company has long recognised the value of customising its cabs to customer specs.

“Some customers want beefed up heaters, for others air conditioning is also a big draw,” Al-Janaby says. “We even get asked to customise the wiper speed.

Made in Canada, Harris-Stolper sends its cabs as “flat-packs” or can install the cabs itself.

“We give the market what it wants,” Al-Janaby adds.

Green Cubes' Robin Schneider and Michael Walsh with the Lithium Safeflex product

Green Cubes' Robin Schneider and Michael Walsh with the Lithium Safeflex product

Michael Walsh, CEO with materials handling-dedicated battery producer Green Cubes, also sees the value in customisable solutions.

At ProMat, Green Cubes was promoting its Lithium Safeflex MHE battery management system which is compatible with AGVs and AMRs.

“Our batteries are customisable and can be sized according to the customer’s needs,” Walsh explains. “It’s what is needed in the market.”

Given that Ali Jones, vice president of sales with forklift fleet management system provider Elokon says some some 85% of facilities in the US have a mixed fleet of forklifts, the need for products to be able to be fitted across a fleet is proving to be essential.

At ProMat, Elokon was promoting its new ELOfusion AI camera system which it says seamlessly integrates forklift fleet telematics with ultra-wideband pedestrian alerts and which can be fitted to mixed-fleets.

“Before integrated telematics, you had to use three or four different proprietary softwares to operate your fleet management systems,” Jones adds. “There is no one solution for everyone. You need different approaches for different applications in different environments.”

Whether you believe the future will see more collaboration or more customisation, it is clear the market is shifting and attitudes are changing quickly as new technology continues to challenge how we see the materials handling sector and its future.

You can check out our gallery of the event here.