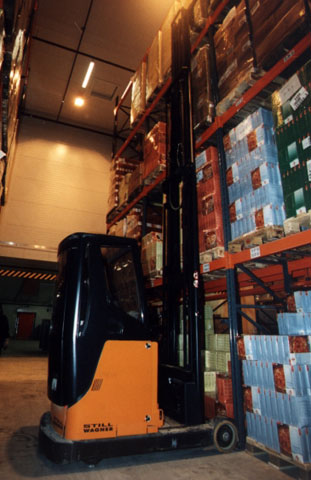

Jungheinrich ETV 216 working in a cold room. |

by

Christine LiewWhen the layperson thinks of forklifts working in sub-zero temperatures like in a gigantic freezer, he or she thinks it must be icy cold. And the floor must be slippery and dangerous.

This could be the case, but seldom is. Cold room floors are usually dry and ice is more likely to form on the forklift than on the floor.

David Hoover, president of Forklift Training Systems Inc, in Ohio, US, says the floor is a "minimal hazard" if forklifts drive the way they're supposed to.

"Everyone drives in rain and snow with a car. That is no reason for an accident, unless you drive too fast or don't pay attention. Same goes for forklifts."

Joseph Hrinik, a US forklift safety researcher, agrees.

"In my experience, icing is seldom a problem unless a product spill freezes. It's similar to driving a car on the highway in winter when it's below freezing but it's not snowing. Traction is quite good."

Forklift manufacturers are more concerned about ice forming on the workhorse and preventing it from functioning.

Icy forklift more likelyHyster Company's Bobby Hopkins says the most important thing to consider for cold room forklifts is the temperature ranges to which they are exposed.

A Linde forklift at work in a cold environment. |

"The environment the forklift is exposed to must be well defined so the suitable cold storage option can be selected when the forklift is manufactured."

Does the forklift work in below -10°C temperatures? Does it go in and out of the cold room? Or does it stay in the cold room the whole time?

Generally, -30°C is the lowest temperature forklift manufacturers cater most commonly for in their cold room options. Still says its cold room forklifts can work in -45°C - but only "briefly". BT says its forklifts can be used in temperatures down to -10°C before cold room protection is needed. However, the forklift must always be parked outside as condensation may occur during the in-out work cycle.

Cold room forklifts are usually parked outside the cold environment when not in use or when being charged and maintained. Condensation can occur because of the higher humidity outside. Before the forklift re-enters the cold room, it must be completely dry either by leaving it outside for a long period or with the assistance of fans. This helps prevent ice from forming when it enters the cold room.

Toyota Material Handling Europe (TMHE) senior applications manager, Magnus Senneryd, sums it up by saying: "Cold store forklifts not only have to withstand very low temperatures but deal with condensation that may accumulate while they move from cold store to warmer areas."

However, he does recommend a "temperature zone" as the best way to prevent ice forming on the forklift. It's a zone where the temperature is around 0°C and has low humidity. Located directly outside the cold room, the zone ensures there is not a lot of mist on the forklift when it spends time outside the cold room.

"Compare to this a room outside the cold room with 25-30°C and high humidity. The forklift will become very wet within a few seconds of exiting the cold room.

"When the forklift re-enters the cold room, it will be covered in ice before it is dry."

And if you are still worried about the floors, forklift trainer Todd Brennan from Forkpro Australia, in Sydney, Australia, says some forklifts come with wire impregnated tyres.

Linde Material Handling's order pickers work on special metal platforms that have wires to prevent the forklifts from skidding as they move on the platform.

But generally, manufactures and forklift safety experts agree skidding is not a problem if forklift operators drive as they are trained.

The cold room forkliftSafety experts say internal combustion engine (IC) forklifts must not be used in cold rooms or any other confined spaces.

IC forklifts emit gas fumes and heat that will increase a cold room's temperature while combustion exhaust by-products like carbon monoxide, smoke and particulates could pose health hazards for workers in a cold room that has no fresh air ventilation.

Leading forklift manufacturers Toyota and Linde manufacture a cold room option for most of their forklifts. Toyota Material Handling Europe markets cold storage versions of both Toyota and BT brand equipment, including electric counterbalanced forklifts and warehouse equipment. Linde has cold room versions of its pallet stackers, pallet trucks, reach trucks and order pickers. Hyster, Still, Crown and Jungheinrich are also well known for their cold room forklifts.

BT Reflex cold store reach truck open cabin. |

The cold room forklifts' components are designed for low temperatures. BT Reflex cold room reach trucks for example, are different from the standard reach truck in these ways:

- -Microswitches and electrical components and motor designed for cold temperature.

- -Hydraulic system's air supply filtered to remove moisture.

- -Hydraulic system contains special low viscosity oil.

- -Stressed fabrications specially checked at all welded joints.

- -Exposed axles and springs made from stainless steel or treated to work in cold temperature.

- -Sheet metal components protected by powder paint.

- -Machined surfaces protected by anti-rust covering.

- -Floor, step and pedals have non-slip covering.

Senneryd says cold room forklifts use a "lighter oil" with lower viscosity. The oil does not affect the forklift's performance.

"Oil gets thicker the colder it is and then the performance in hydraulic functions will be reduced. Therefore, we use oil with lower viscosity in cold store applications to have optimum performance."

Heating is also important - not just for the operator.

Still GmbH's Juergen Wrusch, in Hamburg, Germany, says the forklifts have heating plates and heating resistors distributed over the whole vehicle to keep the major components at service temperature.

A Still cold room option. |

Electric heaters in forklifts use battery current but do not have a big impact on battery life. However, Wrusch says a battery's capacity decreases by approximately 1% for each degree Celcius the temperature drops. Its standard capacity is reached at a temperature of 30°C.

TMHE product marketing manager Anthony Nadalin says the battery life is shorter because the chemical reaction between the battery cell plates are affected by temperature.

Wrusch says the batteries' temperature must not go down to as low as -30°C. They must either be in operation or under charge.

"It is advisable to charge the batteries outside and to continue running the forklift in the cold room using an exchange battery.

If that's not possible and charging must take place inside the cold room, Wrusch advises using "a second energy source" for the forklift's heating system.

Maintenance and service intervals are much shorter for cold room forklifts. For a single-shift operation using a cold room forklift, a maintenance interval can be six weeks or 250 operating hours or a quarter of the interval for standard forklifts. Cold room forklifts may also require an additional weekly inspection.

For extreme cold room applications, the forklift owner should check, among other things, the brake systems' performance, the condition of the wheels, the forks, the steering, the lubrication and the fit of the screw joints.

Cool operatorsSome cold room forklift operators only spend a couple of hours a day in the freezing environment as they are not constantly on the workhorse. These operators are unlikely to work in cabs. However, 10-20% of operators are required to work continuously in the cold room. They not only deck out in winter-style clothing but are confined in a heated and closed-in cab with visibility and hearing restrictions. Safety features apply for both types of operation.

Crown forklift with newly launched ThermoAssist option. |

Specific to the cold room forklifts with cabs is the two-way intercom system that allows the operator to communicate with the outside world. He or she is able to communicate without opening the cab door and can be alerted to external events like alarms.

Linde spokeswoman Heike Oder says the intercom system protects the driver by keeping him or her in the heated cab and also saves heating costs.

She adds it is important to ensure forklift operators are comfortable and do not fall ill in the cold temperature.

"Of course, warm clothing is essential and for cabs, a good heating system.

"Normally, workers on pallet trucks, pallet stackers or order pickers only stay in the cold room a certain amount of time and go somewhere warmer. Reach truck drivers for example, stay in there the whole shift."

Hrinik is concerned about operators getting chilled while rugged up.

"If a heater is used in an enclosed cab, sweating could occur, especially if wearing cold-weather gear. This could cause the operator to chill when working outside of the cab."

He advises operators with a "high chill potential", such as those who frequently get in and out of the cab, to have several changes of clothing.

For those who operate open-cabbed forklifts, fatigue can be a problem. Heating is not available for these operators and so frequent breaks to warm up and close supervision are necessary.

Operators in cold rooms need to be aware that their heavier clothing, footwear and gloves may restrict their movement.

Visibility can be an issue for operators in cabs. Linde boasts of its reach trucks' panoramic, double-glazed polycarbonate windows specific for cold room applications. BT has large plexi-glass windows and an automatic tilt facility for the cab that offers "maximum visibility". Jungheinrich's forklifts have windows with thin, heating wires in between two panes of glass, "invisible to the operator".

Transiting between two temperature zones can fog up operators' safety glasses and cause accidents. Anti-fog safety glasses are also available but Hoover from Forklift Training Systems says they don't seem to work well.

While the cold room floor normally has good traction, it would be irresponsible to end without advising forklift operators to still exercise caution.

Hyster's Hopkins says operators should accommodate the potential for reduced traction by braking smoothly, allowing extra time for braking, and manoeuvring the forklift carefully.

And if the forklift breaks down right in front of a wall or racking, an operator can use an "emergency exit", an extra door for a counterbalanced forklift or a roof exit for a reach truck. Meanwhile, the operator in a man-up forklift who gets stuck 12 metres high will have to don special equipment and abseil down from a hatch in the raised cab's roof.